Plan For Every Part Template & Guide

$30.00

This Plan For Every Part template and guide is written to help supply chain professionals understand data generation points like Modeling, Supplier, Logistic, Demand, Warehouse, Process Plan, Material handler inside the factory, Floor worker, Quality department, and customer data too and how they linked together.

Plan For Every Part (PFEP) can be a ten-time bigger version of the Material Resource Planning (MRP) system, which includes more data points to generate product information and make that information available at the required location or to a responsible person.

This concept originates from the Lean Community. The PFEP defines a plan (at the part level) for the most efficient replenishment and movement of every part used in business through the complete Supply/Value Chain.

I have used this concept during my days as Manufacturing Plant Supply Chain Manager and have reaped many benefits in terms of:

- Finding the right planning policy depends on the stocking procedure.

- Level load production plan, as a result, better efficiency

- Result of improved On-Time Delivery Performance & Reduction of Inventory as main supply chain KPIs.

You can read a detailed blog, What is Plan for Every Part (PFEP)- 4 Levels of Benefits

This practical guide aim to help you understanding PFEP concepts, outline steps of implementation, explain benefits and also challenges you might face during implementation. It also includes example as well.

The guide is a good reference point to understand key challenges and success factors in implementing PFEP.

Plan For Every Part Template

You can download the Plan For Every Part Template along with the Guide.

Each template can involve information only related to that product, and by integrating all the PFEP templates, we can have distortionary about each part.

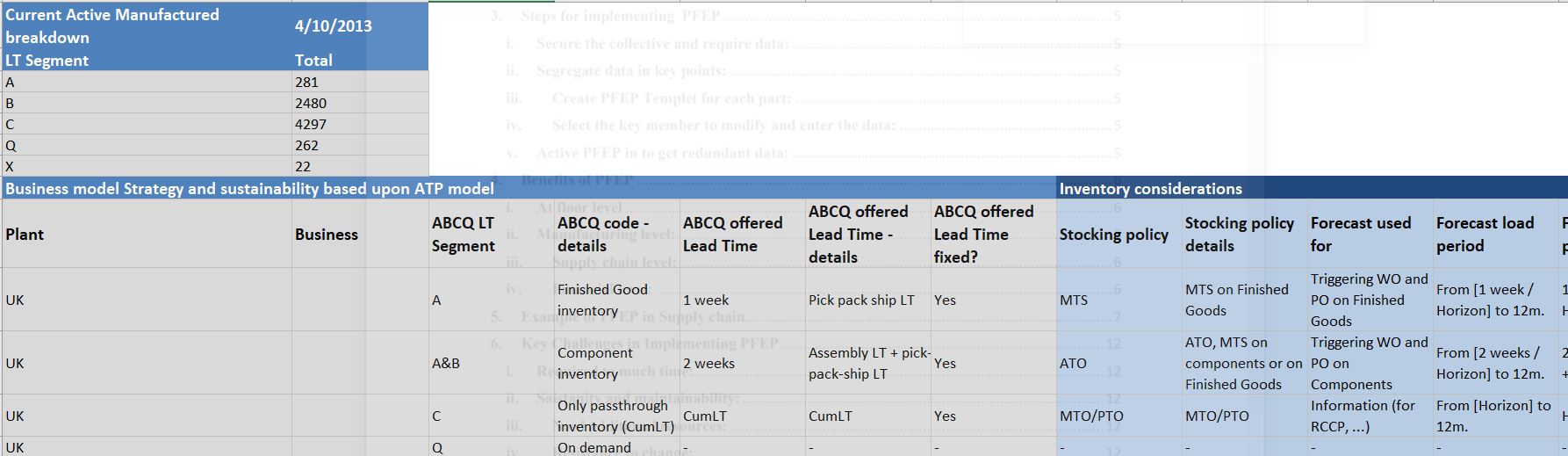

All the parts should be considered in the process even if it costs only one cent, or it’s ordered only once a year. A snapshot is shown below.

We would also recommend watching 5 Levels of Supply Chain Planning to see where these concepts fits well in the overall hierarchy of planning.

Access our E-Books on our Website!

Stocktaking Procedure - The Ultimate Guide

$ 35

Optimize Your Inventory: A Guide to Planning Methods

$ 20

Demand Forecasting Methods - The Ultimate Guide

$ 20

The Most Complete Supply Chain Terms and Glossary

$ 20

Ratings and Reviews

What's your experience? We'd love to know!

Write a ReviewThere are no reviews yet. Be the first one to write one.

No reviews found.

- Upgrade to

Student orPro plan to avail more discounts and perks - Unlimited access, anywhere, anytime

Book Contents

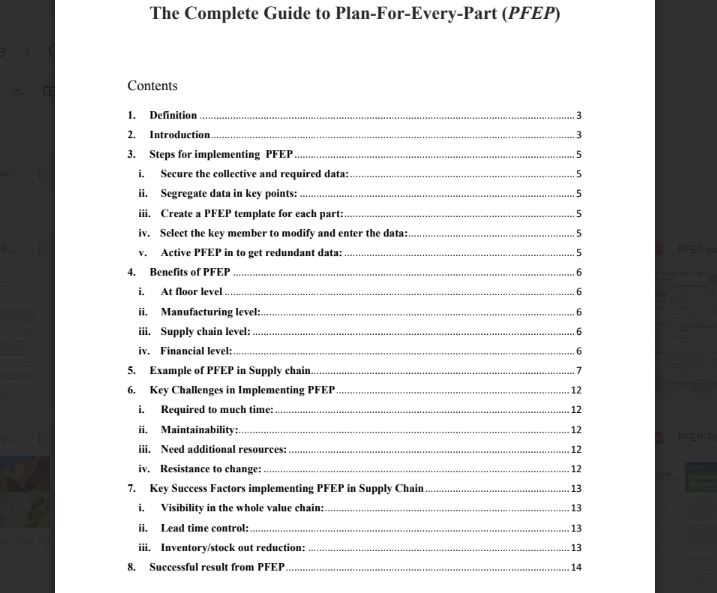

- Definition 3

- Introduction 3

- Steps for implementing PFEP 5

- Secure the collective and require data 5

- Segregate data in key points 5

- Create PFEP Templet for each part 5

- Select the key member to modify and enter the data 5

- Active PFEP in to get redundant data 5

- Benefits of PFEP 6

- At floor level 6

- Manufacturing level 6

- Supply chain level 6

- Financial level 6

- Example of PFEP in Supply chain 7

- Key Challenges in Implementing PFEP 12

- Required to much time 12

- Saistanity and maintainability 12

- Need additional resources 12

- Resistance to change 12

- Key Success Factors implementing PFEP in Supply Chain 13

- Visibility in the whole value chain 13

- Lead time control 13

- Inventory/stock out reduction 13

- Successful result from PFEP 14