Tools

Warehouse Safety Checklist

Warehouse Safety Audit Tool which you can use as a consultant for your company and identify areas for improvements.

The U.S. Department of Labor’s Occupational Health and Safety Administration (OSHA) reports warehouse in America own a disproportionately high accident rate in comparison to other sectors. OSHA also says the fatal injury rate is more than America’s national average for all workplaces.

A closer look at the Bureau of Labor Statistics (BLS) reports provides a better insight into the problems facing warehouses. Their findings support OSHA’s accounts of warehouses having more severe accidents and injury rates. The BLS also highlights these four-outstanding data from the reports:

- The yearly warehouse injury rate in the U.S. is 5 cases per 100 full-time employees.

- The rate of severe injuries stands as 3.7 cases per 100 employees.

- The cases considered less serious is given as 1.7% for warehouse employees.

- Almost all injuries recorded are notably preventable.

The 4th point highlights the importance of the Warehouse Safety Audit. Workplaces who employ the right safety programs are more effective and suffered fewer injuries and less productivity loss.

The significance of the Warehouse Safety Audit from a financial perspective also shows most businesses cannot pay for the outcomes of an unsafe workplace.

Keep this significance in mind SCMDOJO has developed a comprehensive Warehouse Safety Audit Tool which you can use as a consultant for your company and identify areas for improvements.

This self-assessment type Warehouse Safety Audit Tool also:

- Encourages employee’s involvement and responsibility in driving warehouse safety improvement.

- Encourages staff to reflect on their role and contribution to the key warehouse safety awareness.

- Allows staff to see and reflect on their peers’ assessment of their contribution.

- Focuses on the development of employees’ judgment skills

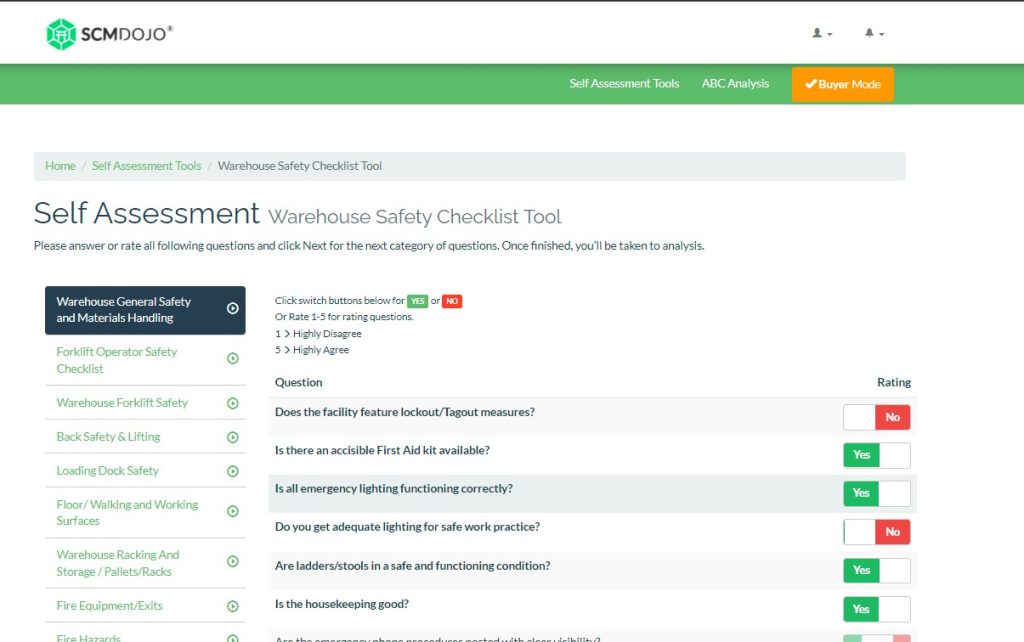

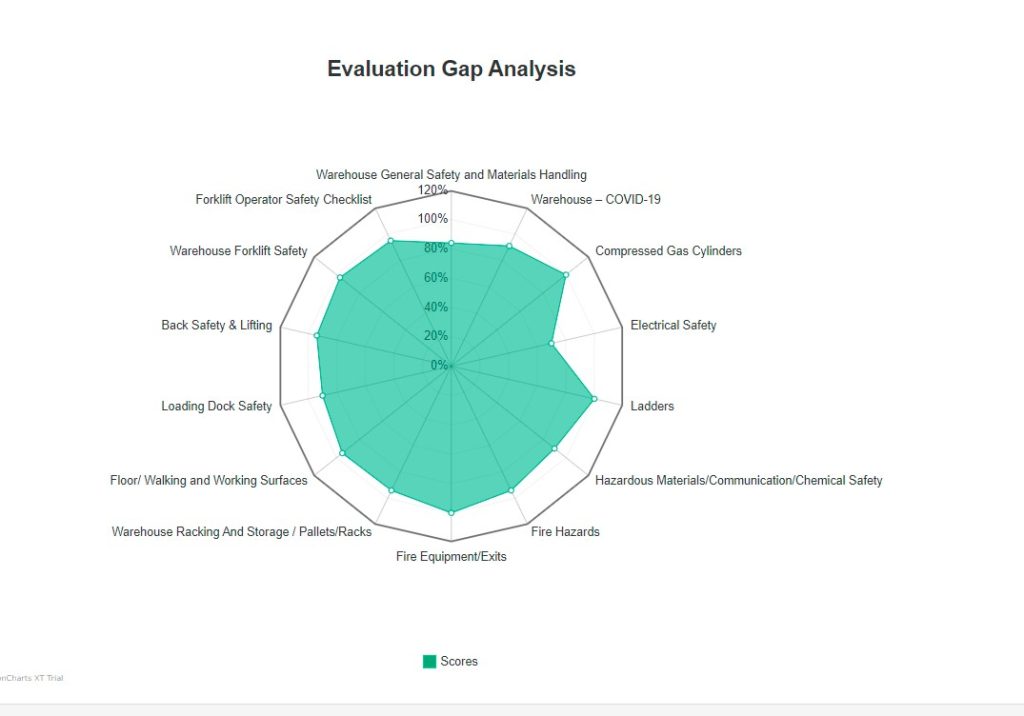

For warehouse working environments, the 14 Categories to Consider includes:

- Warehouse General Safety and Materials Handling

- Forklift Operator Safety Checklist

- Warehouse Forklift Safety

- Back Safety & Lifting

- Loading Dock Safety

- Floor/ Walking and Working Surfaces

- Warehouse Racking And Storage / Pallets/Racks/Storage Practices

- Fire Equipment/Exits

- Fire Hazards

- Hazardous Materials/ Hazard Communication/Chemical Safety

- Ladders

- Electrical Safety

- Compressed Gas Cylinders

- Warehouse – COVID-19

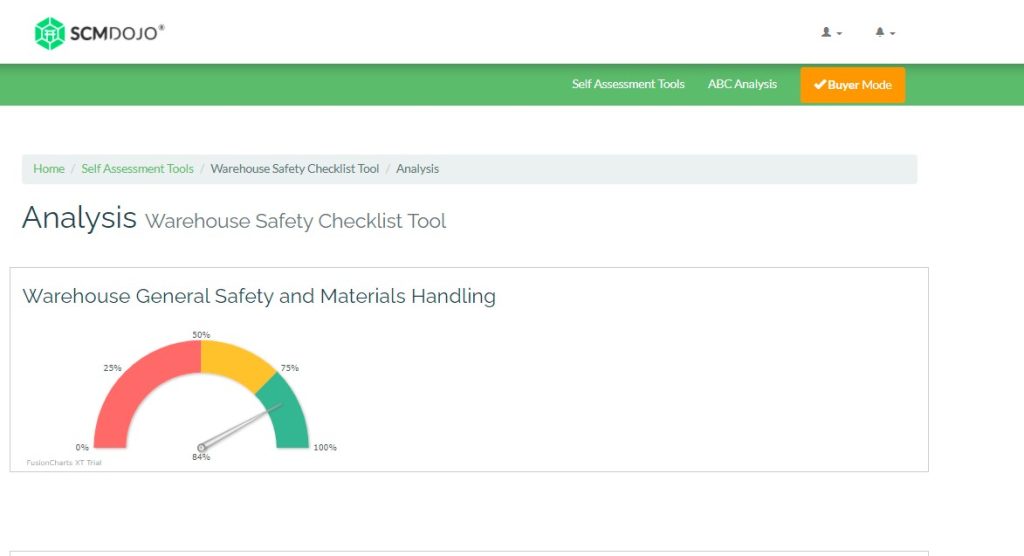

You need simply select Yes and No choices for each category, If N/A is selected, it will not be accounted for in the total score. Once you complete the self-assessment you will get 3 graphs as shown below.

Here are Quick Steps to Access the Assessment

1. Login or Sign using your email

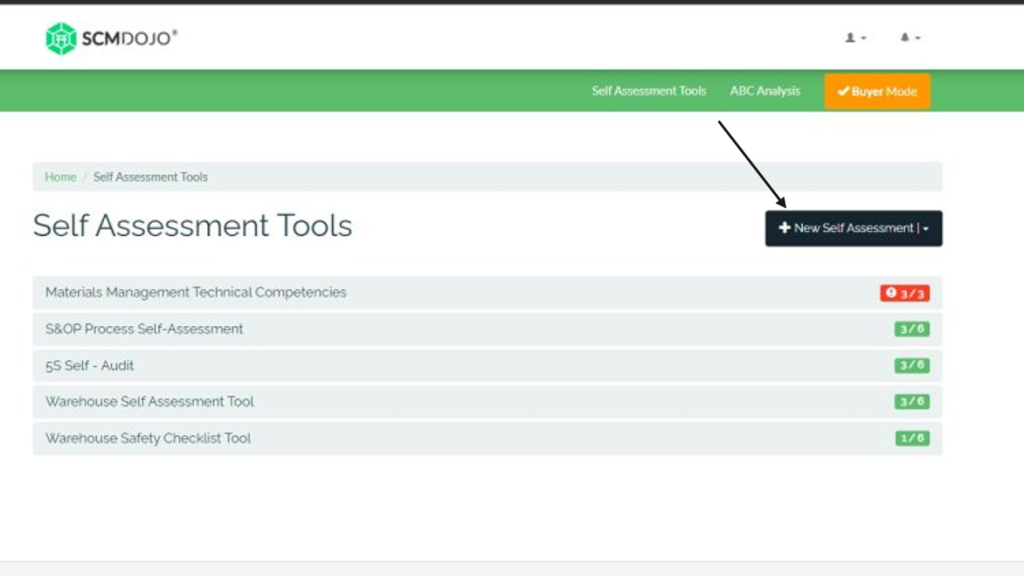

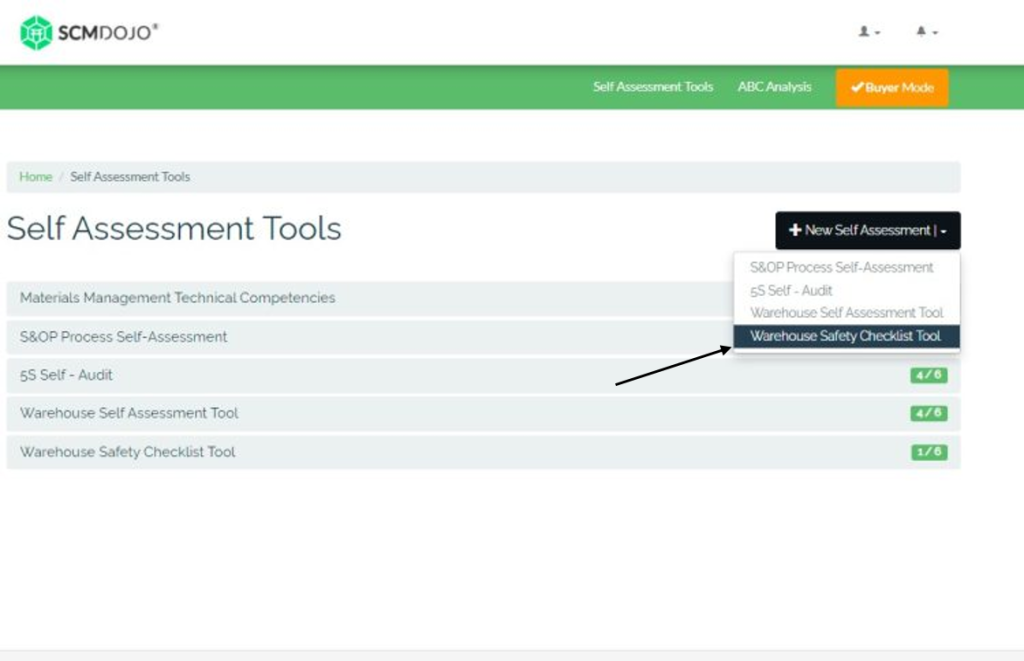

2. Click on "New Self Assessment"

3. Under Warehouse Safety Checklist Tool click on Start- Self Assessment

4. Continue selecting Yes or No in each Category

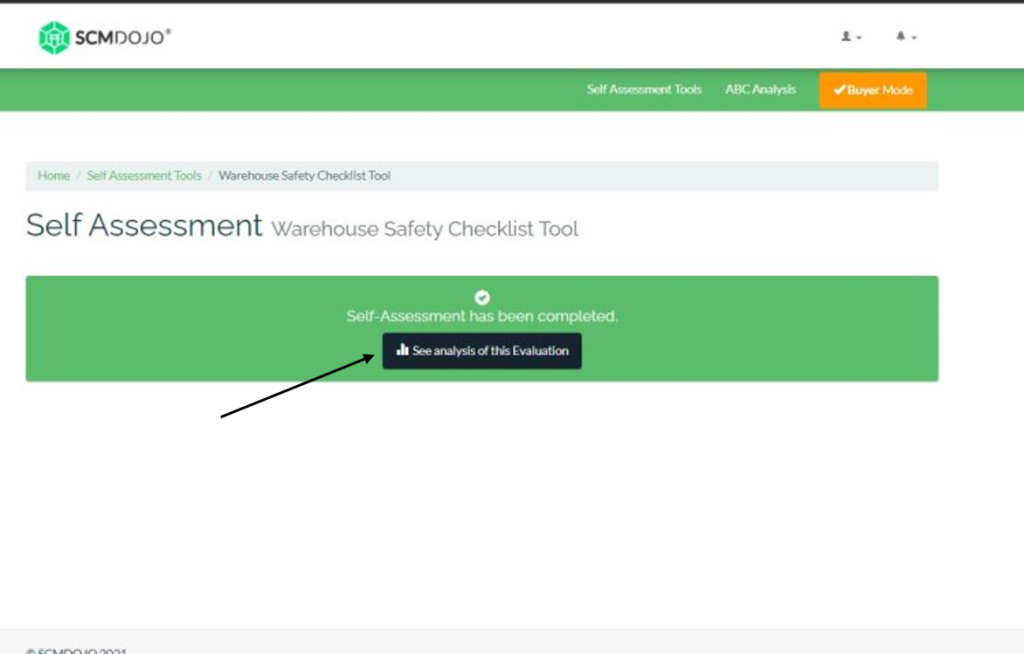

5. Complete the Self-Assessment and Click on “ See Analysis of this Evaluation”

6. Review the Analysis and Graph & Table to see your total score in each category

With this as Ad-on, I have given almost 50% discount on

- Best Warehouse Audit Tool to Improve Performance

To understand your current knowledge and skills status I have designed this Materials Management Competency Assessment tools.

To deploy a successful Sales and Operations Planning Process, we have built this simple yet very effective S&OP Maturity Model Self-Assessment tool