Tools

Warehouse Operations Assessment

How do you know your warehouse is performing to good standard? This warehouse audit tool enables you to identify areas for improvements.

How do you know your warehouse is performing to a good standard? This warehouse audit tool enables you to identify areas for improvement and measure your warehouse performance.

This Self-Assessment type Warehouse Audit Tool also:

- Encourages employee’s involvement and responsibility in driving warehouse improvement.

- Encourages staff to reflect on their role and contribution to the key warehouse processes.

- Allows staff to see and reflect on their peers’ assessment of their contribution.

- Focuses on the development of employees’ judgment skills

This tool is developed as a result of a research project with Manchester Business School.

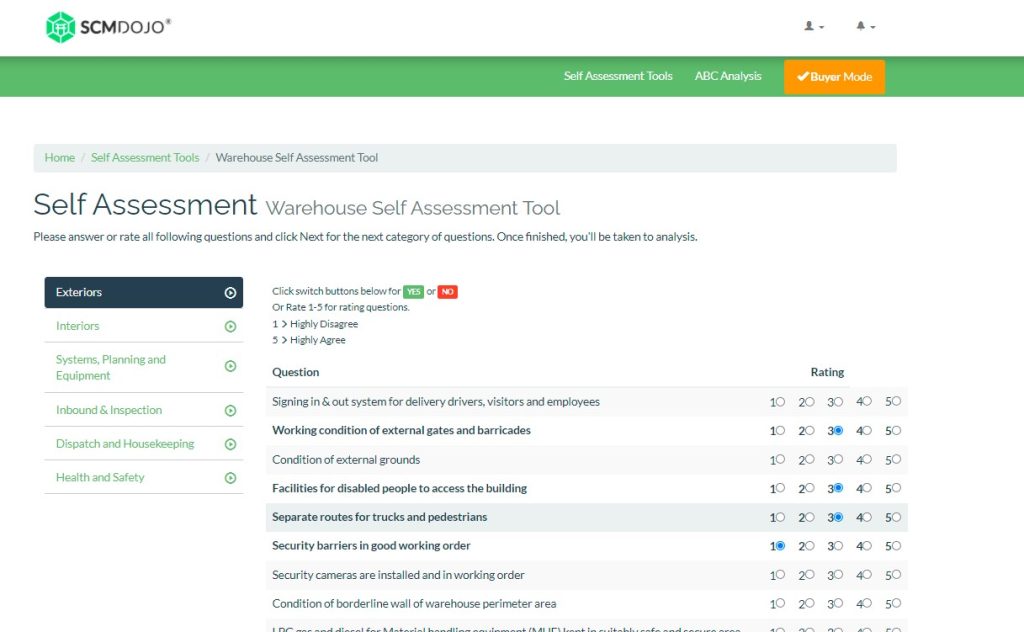

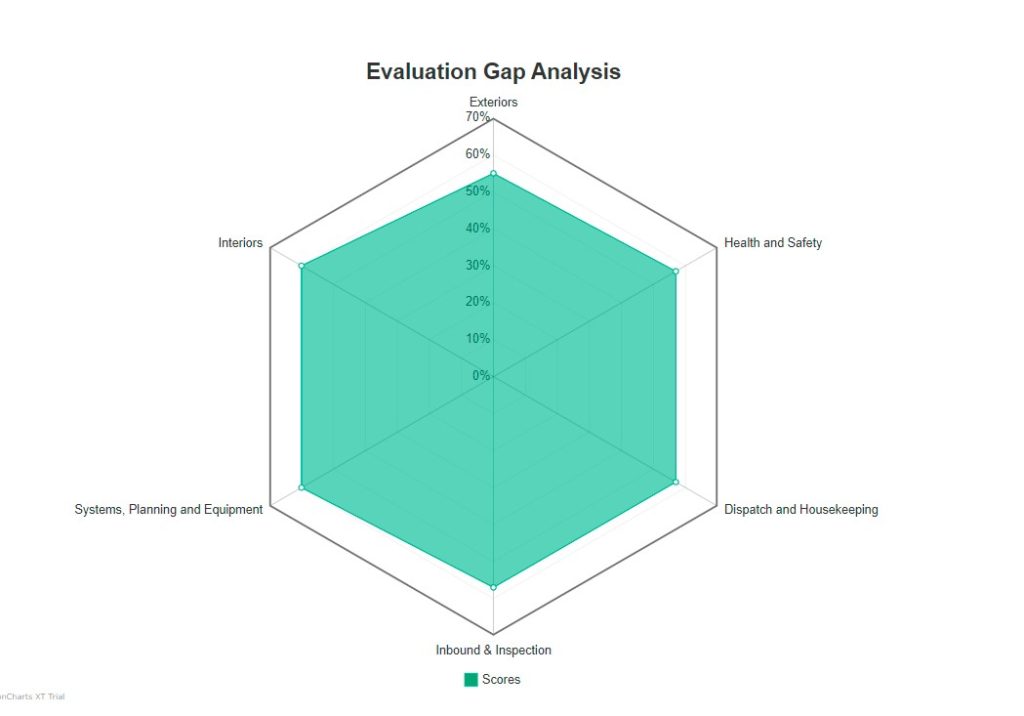

This comprehensive & tested warehouse assessment tool has 184 questions in below mentioned 6 Categories.

Warehouse Audit

184 Criteria Questions in all 6 Categories

- Exteriors

- Interiors

- Systems, Planning and Equipment

- Inbound & Inspection

- Dispatch and Housekeeping

- Health and Safety

- You will get curated lists for Supply Chain Books, Courses and Best Practices to close the Knowledge- Gap on low scoring Categories.

As a Manager or staff, you need to be aware of warehouse processes that need to be planned and controlled include:

“inbound flow handling, product-to-location assignment, product storage, order-to-stock location-allocation, order batching and release, order picking, packing, value-added logistics activities, and shipment (Ackerman, 1980).”

6 Categories of Warehouse Audit Tool

In this warehouse audit tool characteristics (indicators) and dimensions of warehouse management will be examined under 6 parts-

- Internal Areas – Security check, safety briefing, floor plan, ventilation, and many more.

- External Areas – Signboards, routes, lighting, parking and many more.

- Systems, Planning and Equipment – IT systems, mechanical handling equipment, key warehouse processes, movement of goods, vehicle booking system, scheduling of vehicles.

- Health and Safety – Internal H&S, external H&S, staff awareness and many more.

- Inbound & Inspection – non-conformance product and packaging, scheduling of vehicle arrivals.

- Despatch, Housekeeping and Performance Measurement – Picking, warehouse performance management, training, shift allocation, employee utilisation and many more.

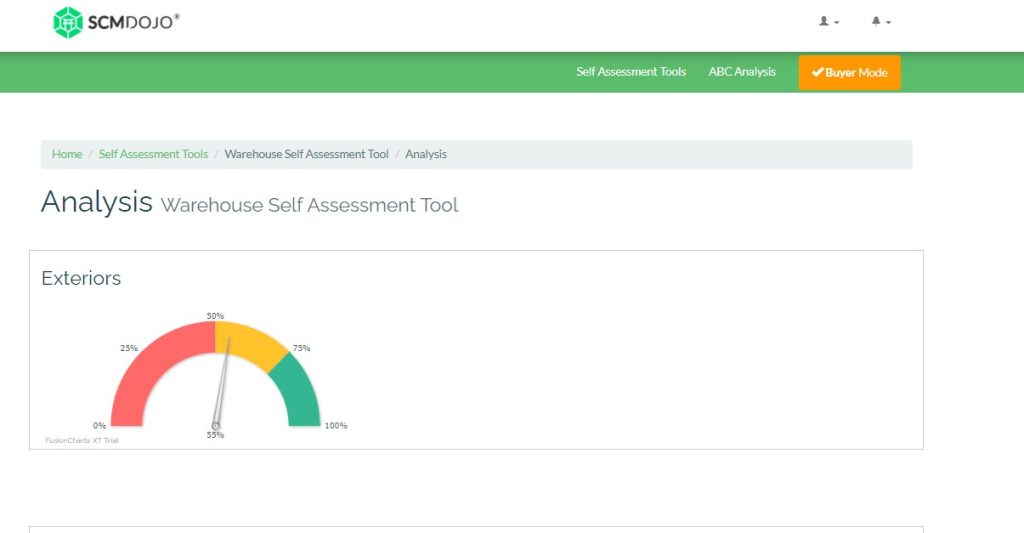

You need simply select 1 of the 5 choices on Likert scale. If N/A is selected, it will not be accounted for in the total score. Once you complete self-assessment you will get 3 graphs as shown below.

In the last decade, we observed an increasing complexity in warehouse operations. This complexity is very well demonstrated by the implementation of sophisticated IT tools in warehouses and distribution centers (DCs). Therefore, we need a comprehensive warehouse audit program & warehouse audit plan to assess this complexity and identify any blind spot

Lastly, the main aim of the above-mentioned categories and questions in this warehouse audit tool, is to guides you towards Best practices in warehousing operations.

You can also find Materials Management Technical Competencies Self Assessment tool & Sales and Operations Planning Process – Self-Assessment useful to improve you materials management & S&OP processes.

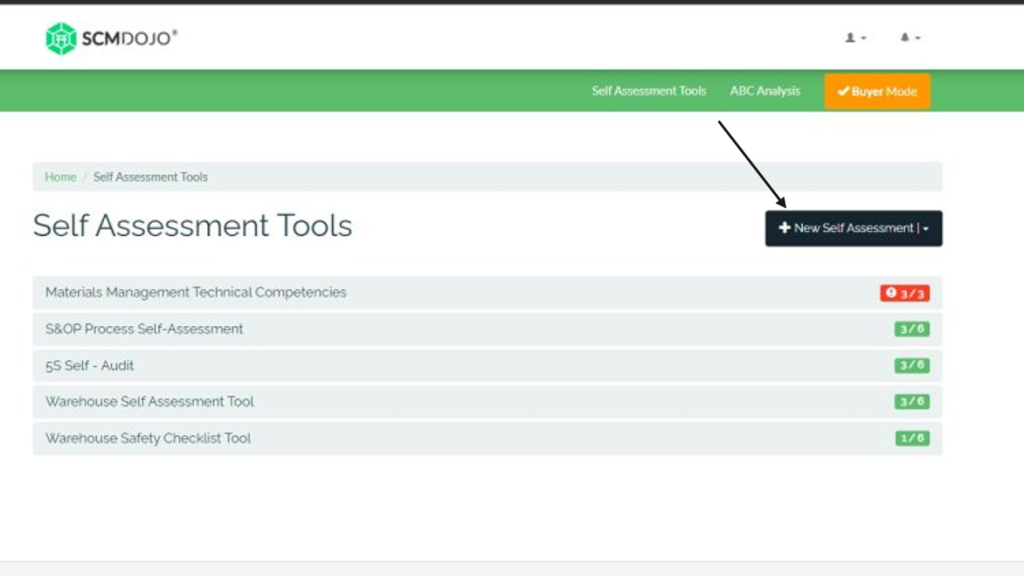

Here are Quick Steps to Access the Assessment

1. Login or Sign using your email

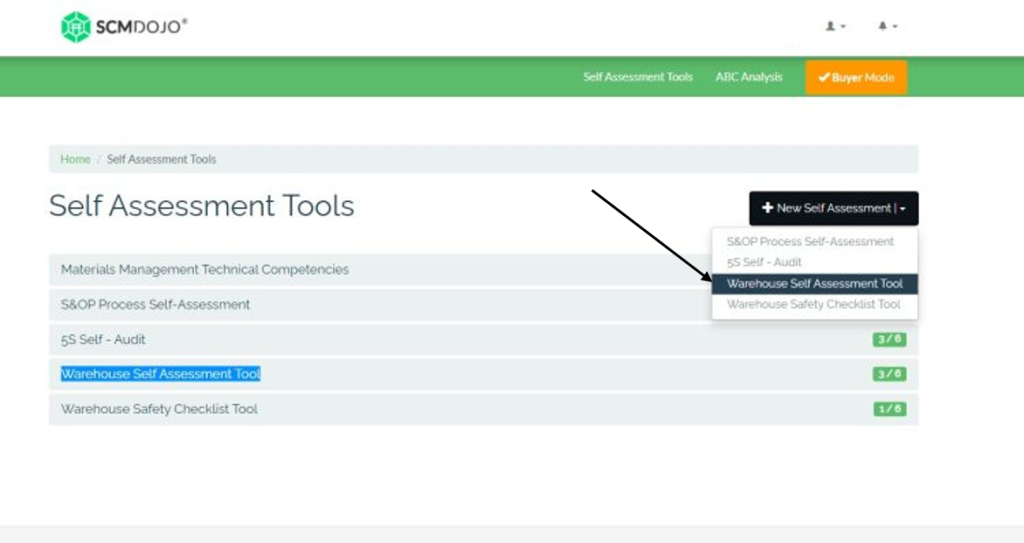

2. Click on "New Self Assessment"

3. Under Start- Self Assessment click on tWarehouse Self Assessment Tool

4. Continue selecting Yes or No in each Category

5. Complete the Self-Assessment and Click on “ See Analysis of this Evaluation”

6. Review the Analysis and Graph & Table to see your total score in each category

To understand your current knowledge and skills status I have designed this Materials Management Competency Assessment tools.

To deploy a successful Sales and Operations Planning Process, we have built this simple yet very effective S&OP Maturity Model Self-Assessment tool