Warehouse Safety Audit Tool

- 1 Files

- 794.51 KB

$49.00

Why gamble with warehouse safety? SCMDOJO’s Warehouse Safety Audit Tool offers a comprehensive solution to mitigate risks, fostering employee involvement and accountability for a safer workplace. Take control of safety today.

Why is a Warehouse Safety Audit Important?

According to the U.S. Department of Labor’s Occupational Health and Safety Administration (OSHA), warehouses in America possess a disproportionately high accident rate compared to other sectors. OSHA also notes that the fatal injury rate exceeds the national average for workplaces across the nation.

A closer examination of reports from the Bureau of Labor Statistics (BLS) offers deeper insights into the challenges confronting warehouses. Their findings corroborate OSHA’s observations about warehouses experiencing more severe accidents and higher injury rates. The BLS also underscores these four notable points from their reports:

- The annual warehouse injury rate in the U.S. is 5 cases per 100 full-time employees.

- The rate of severe injuries is 3.7 cases per 100 employees.

- Cases classified as less severe amount to 1.7% for warehouse employees.

- Almost all recorded injuries are notably preventable.

The fourth point emphasizes the significance of Warehouse Safety Audits. Workplaces that implement effective safety programs are not only more efficient but also witness fewer injuries and experience less productivity loss.

The financial importance of the Warehouse Safety Audit is underscored by the fact that most businesses are unable to bear the costs associated with an unsafe workplace.

With this significance in mind, SCMDOJO has meticulously crafted a comprehensive Warehouse Safety Audit Tool. This tool can serve as a valuable resource for consultants within your company, helping you identify areas for improvement and ensuring a safer working environment.

Why you should buy this tool?

This Warehouse Safety Audit Tool, designed as a self-assessment, also:

- Encourages employee involvement and accountability in enhancing warehouse safety.

- Promotes staff reflection on their roles and contributions to crucial warehouse safety awareness.

- Provides a platform for staff to view and consider their peers’ evaluations of their contributions.

- Centers around fostering the development of employees’ judgment skills.

Read more on 10 Disastrous Warehouse Accidents: Reasons & Solutions on our website SCMDOJO!

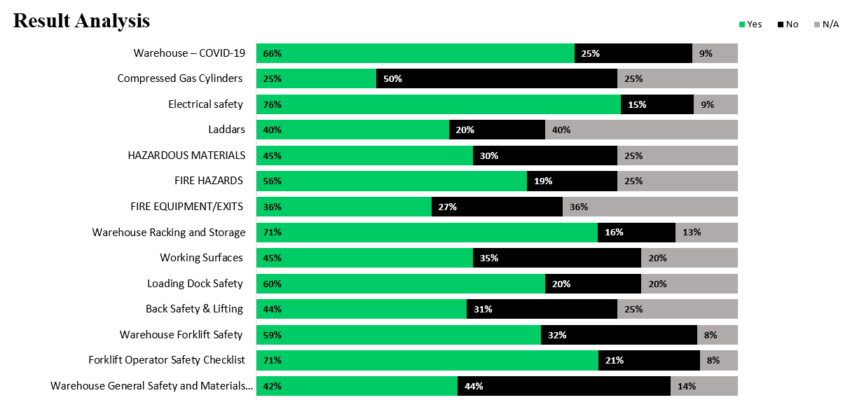

In the context of warehouse working environments, the 14 categories to consider are as follows:

- Warehouse General Safety and Materials Handling

- Forklift Operator Safety Checklist

- Warehouse Forklift Safety

- Back Safety & Lifting

- Loading Dock Safety

- Floor/ Walking and Working Surfaces

- Warehouse Racking And Storage / Pallets/Racks/Storage Practices

- Fire Equipment/Exits

- Fire Hazards

- Hazardous Materials/ Hazard Communication/Chemical Safety

- Ladders

- Electrical Safety

- Compressed Gas Cylinders

- Warehouse – COVID-19

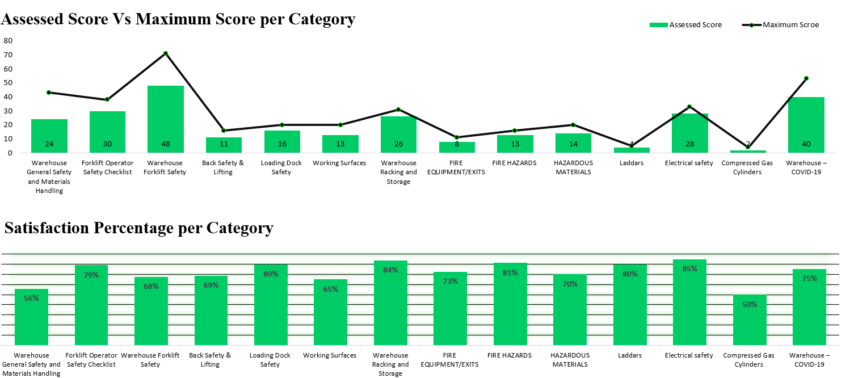

You simply need to select “Yes” and “No” choices for each category. If “N/A” is chosen, it will not be factored into the total score. Upon completing the self-assessment, you will receive three graphs as depicted below.

Watch this video on Warehouse Safety – Why sleep is crucial?

Access our Best Practices on our Website!

Logistics KPI Dashboard Excel Template

Ratings and Reviews

What's your experience? We'd love to know!

Write a ReviewThere are no reviews yet. Be the first one to write one.

No reviews found.

- Upgrade to

Pro plan to avail more discounts and perks - Unlimited access, anywhere, anytime

- Single-User License

- One-Time Payment

- Instant Download

Files Included

| 1 | Warehouse Safety Audit | 794.51 KB |

| 794.51 KB |