Economic order quantity is one of the “most commonly used inventory-control techniques”. The objectives and advantages of Economic Order Qty (EOQ) are to minimize inventory carrying costs and ordering costs while simultaneously limiting the probability of stock out to avoid any lost sales or customer loss.

Like safety stock calculations, EOQ is one of the most important equations in supply chain planning.

What is Economic Order Quantity (EOQ) Equation & Graph:

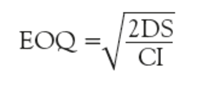

The basic formula is as follows:

EOQ = Economic Order Quantity,

C = Cost of the item,

I = Annual inventory carrying cost,

D = have different names: “Annual anticipated demand”, or “annual sales volume/ unit”, “forecasted demand”, and “annual usage rate”.

S = Cost per order.

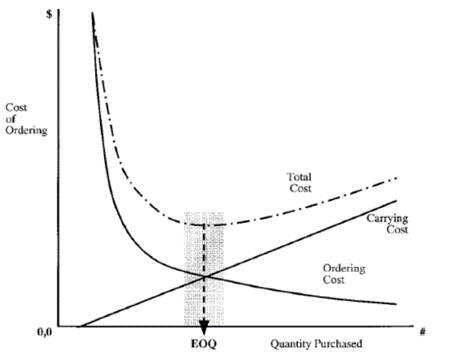

The graph is as follows:

According to the graph above. The Economic Order Qty (EOQ) is trying to balance the carrying and ordering costs.

Economic Order Quantity (EOQ) Problems and Limitations:

While the model of Economic Order Qty (EOQ) is very beneficial and easy to apply. The model presupposes the following presuppositions, which appear to be problematic and unrealistic to any supply chain practitioner :

- That the demand is known, certain and constant over time:

We live in a VUCA world (volatile, uncertain, complex and ambiguous). The demand is subjected to change due to many factors drastically, including pandemics (COVID-19), war (Russia-Ukraine war), and last but not least technological advancements.

- That there are no constraints on lot size:

Suppliers do sometimes request a minimum order quantity or the stock keeping unit comes in a specific package with a specific quantity. So, the calculated Economic Order Qty (EOQ) might be a small value, while the minimum order quantity by the supplier might be a higher value. In other words, in real life there are constraints on the order quantity from the supplier’s side.

- That the only relevant costs are holding costs, setup and ordering costs:[3]

While Total Landing Cost (TLC) includes other types of costs like; transporting, storage, risk, delivery, and quality, and the more complicated analysis, the Total cost of ownership (TCO), includes the TLC, in addition to the ongoing lifetime, operating, durability, end-life disposal cost, …etc.

We recommend taking a very detailed course by SCMDOJO Expert Corey Weekes on Total Cost to Ownership & Serve.

- The price is constant and independent to the quantity and time:[4]

The equation assumes that the cost of item (C) is constant regardless of the quantity and time of placing the order. In real life, the price of an item might decrease or increase depending on the quantity ordered from the supplier.

- That the Lead time is constant and known with certainty and always consistent

With the rise of COVID-19, the supply chain in is facing a huge challenge in the lead time. And as mentioned above one of the main characteristics of this era is the

uncertainty in the lead time (“U” in the jargon “VUCA”). This presupposition is apparent with the absence of the lead time in the Economic Order Qty equation (EOQ) equation.

- There is no limit on the order size due to the storage capacity:

The warehouse might have two concerns; the first is related to the capacity of the warehouse. The second is whether the warehouse is prepared to receive this product.

While the previous points of criticism are valid and worth considering, EOQ might help procure both; the repetitive items and the MRO (maintenance, repair and operation) items. The aim of this article to show that while the Economic Order Qty (EOQ) is a well-known model, it has its limits. So, if you are a supply chain professional and apply this model in your industry, you have to review the results of your planning efficiency.

Author: Emad Atef – CSCA, MBA (Candidate), Procurement and Sourcing Manager.

Please follow Emad on LinkedIn to appreciate his contribution.

References

Bowersox, Supply Chain Logistics Management. Donald J. Bowersox, David J. Closs, M. Bixby Cooper, 166; Lysons, Procurement & Supply Chain Management, 9th Ed., 312.

Lysons, Procurement & Supply Chain Management, 9th Ed., 312.

Daniel Stanton, Supply Chain Management For Dummies, 1st edition (Hoboken, NJ: For Dummies, 2017), 142.

Bowersox, Supply Chain Logistics Management. Donald J. Bowersox, David J. Closs, M. Bixby Cooper, 166.

Bowersox, 166; Lysons, Procurement & Supply Chain Management, 9th Ed., 312; Heizer, Operations Management, 507.

Lysons, Procurement & Supply Chain Management, 9th Ed., 312; Chopra, Supply Chain Management, 273; Heizer, Operations Management, 507.

Lysons, Procurement & Supply Chain Management, 9th Ed., 312; Bowersox, Supply Chain Logistics Management. Donald J. Bowersox, David J. Closs, M. Bixby Cooper, 166; Sunil Chopra, Supply Chain Management: Strategy, Planning, and Operation, Global Edition: Strategy, Planning, and Operation (Boston: Pearson, 2015), 273; Heizer, Operations Management, 507.

Emad Atef Ezzat, “Supply Chain Post COVID-19: ‘VUCA’, ‘Black Swan’, and ‘Perfect Storm’:,” Supply Chain for Beginners (blog), July 10, 2021, Accessed on 14-1-2022, https://supplychain4beginners.wordpress.com/2021/07/11/supply-chain-post-covid-19-vuca-black-swan-and-perfect-storm/.

Jay & Barry Render Heizer, Operations Management, 10th edition (Boston Munich: Pearson, 2011), 507.

Stephen P. Robbins, David A. Decenzo, and Mary Coulter, Fundamentals of Management: Essential Concepts and Applications, 7th edition (Upper Saddle River, N.J: Pearson College Div, 2010), 123; Donald J. Bowersox, Supply Chain Logistics Management. Donald J. Bowersox, David J. Closs, M. Bixby Cooper, 3rd edition (Boston: McGraw-Hill, 2009), 164; Michael H. Hugos, Essentials of Supply Chain Management 2nd (Second) Edition Text Only, n.d., 63.

Kenneth Lysons, Procurement & Supply Chain Management, 9th Ed., 2016, 312. Lysons, 312.

Bowersox, Supply Chain Logistics Management. Donald J. Bowersox, David J. Closs, M. Bixby Cooper, 165.

Robbins, Decenzo, and Coulter, Fundamentals of Management, 124.

Hugos, Essentials of Supply Chain Management 2nd (Second) Edition Text Only, 60-61.

Bowersox, Donald J. Supply Chain Logistics Management. Donald J. Bowersox, David J. Closs, M. Bixby Cooper. 3rd edition. Boston: McGraw-Hill, 2009.

Chopra, Sunil. Supply Chain Management: Strategy, Planning, and Operation, Global Edition: Strategy, Planning, and Operation. Boston: Pearson, 2015.

Ezzat, Emad Atef. “Supply Chain Post COVID-19: ‘VUCA’, ‘Black Swan’, and ‘Perfect Storm’:” Supply Chain for Beginners (blog), July 10, 2021. https://supplychain4beginners.wordpress.com/2021/07/11/supply-chain-post-covid-19-vuca-black-swan-and-perfect-storm/.

Heizer, Jay & Barry Render. Operations Management. 10th edition. Boston Munich: Pearson, 2011.

Hugos, Michael H. Essentials of Supply Chain Management 2nd (Second) Edition Text Only, n.d.

Lysons, Kenneth. Procurement & Supply Chain Management, 9th Ed., 2016.

Robbins, Stephen P., David A. Decenzo, and Mary Coulter. Fundamentals of Management: Essential Concepts and Applications. 7th edition. Upper Saddle River, N.J: Pearson College Div, 2010.

Stanton, Daniel. Supply Chain Management For Dummies. 1st edition. Hoboken, NJ: For Dummies, 2017.