In early July I wrote a blog on “7 reasons why Six Sigma will fail in Small & Medium Enterprises (SMEs)” which has gathered some interest and couple of readers have asked me what are the success factors of Lean and Six Sigma deployment in SMEs, if there is any? I thought it is valid questions and I should try to research some Critical Success Factors (CSFs) of Lean and Six Sigma deployment in SMEs.

Get 5S – Kaizen Guide to Organize the Workplace for Flow

In this blog post I have tried to focus on research from Achanga et al. (2006) and Kumar (2007). Achanga et al. (2006) have successfully completed case research in ten Small & Medium Enterprise (SMEs) in the East of the UK, which had implemented lean manufacturing in their firms. The research outlines the issues that were fundamental to their successes in implementing the concept. A research methodology comprises of literature review, observation of companies’ practices and personal interviews. As the research outcome the most pertinent critical factors that determine the successful implementation of lean manufacturing concept within SMEs environment are:

1) Leadership

2) Management

3) Finance

4) Organizational culture

5) Skills & expertise

To share my experience and knowledge bank I have complied 4 special Six Sigma project tools which will help you complete the Six Sigma project successfully.

Best Plagiarism Checker & Proofreader

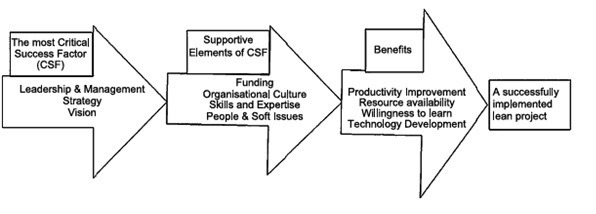

As shown in figure below Strong leadership committed & management support is the cornerstone to the success of implementing any idea within an organisation.

Kumar (2007) has done a single case study in UK manufacturing SME by using survey and semi structured interviews to identify CSFs of Six Sigma; familiarity Six Sigma tools and techniques with in employee; and organisations performance review after Six Sigma implementation. The study done by Kumar (2007) also identify hurdles face by selected SME in Six Sigma journey. The five most CSFs found in this study for Six Sigma in SME is:

1. Management involvement and commitment.

2. Linking Six Sigma to customer.

3. Cultural change.

4. Education and training.

5. Vision and plan statement supported by CEO.

The main impeding factors in the deployment of Six Sigma identified by 56% of respondents are the availability of resources and poor training/coaching. Along with this 44% of respondents think lack of leadership support and 49% things changing business focuses could hamper the successful deployment of Six Sigma within the organisation. One interesting finding that was never identified in literature before was the lack of support from middle manager.

To conclude the common CSFs for both Lean and Six Sigma implementation in SME outlined in research articles by Kumar (2007) & Achanga et al.(2006) are:

1. Leadership commitment and management involvement.

2. Orgasational culture

3. Resource in terms of education and training.

The framework presented by Kumar et al… (2007) is predominantly followed Six Sigma DMAIC framework while using lean tools such as 5s, Value Stream Map (VSM), Total productive maintenance (TPM) in each of Six Sigma DMAIC phases.. Also, in general, there is no standard framework for Lean Sigma implementation and there is no clear understanding on the usage of tools and techniques within the Lean Sigma framework. The above described CSF for Lean and Six Sigma implementation in SME is also mandatory steps in general Lean and Six Sigma deployment models presented by Womack and Jones (2003) & Magnusson et.al (2003), however, on the other hand Beaver and Prince (2004) argues that the management theories and enterprise research that have been developed and applied to the corporate sector are difficult to replicate in small business, as the SME’s is not a large one in miniature and are not simply the scale-down version of large ones which raise a question on what extent of modification required to existing models of Lean and Six Sigma individually or as integrated approach to fits in to SME environment

Let me know what are the other contributing critical successes factors are in deployment of Lean and Six Sigma tools in SMEs from your experience, would be great to add few more in the list!

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram