Time is really important in business. Studies say that 25% of customers won’t buy something unless it can be shipped in two days or less. Knowing how crucial time is for keeping customers happy and influencing what they buy, it’s clear that handling lead time (which means the time it takes to get things ready) is not just needed for business, but it also gives an edge in today’s competitive and complex economy. To make things simpler, having a clear lead time definition helps in making sure orders are fulfilled on time and customers are satisfied.

With this in mind, we will explore in this blog the definition of Lead Time, its impact, and how mastering it can be your competitive advantage.

Discovering Lead Time: A Simple Definition and Types

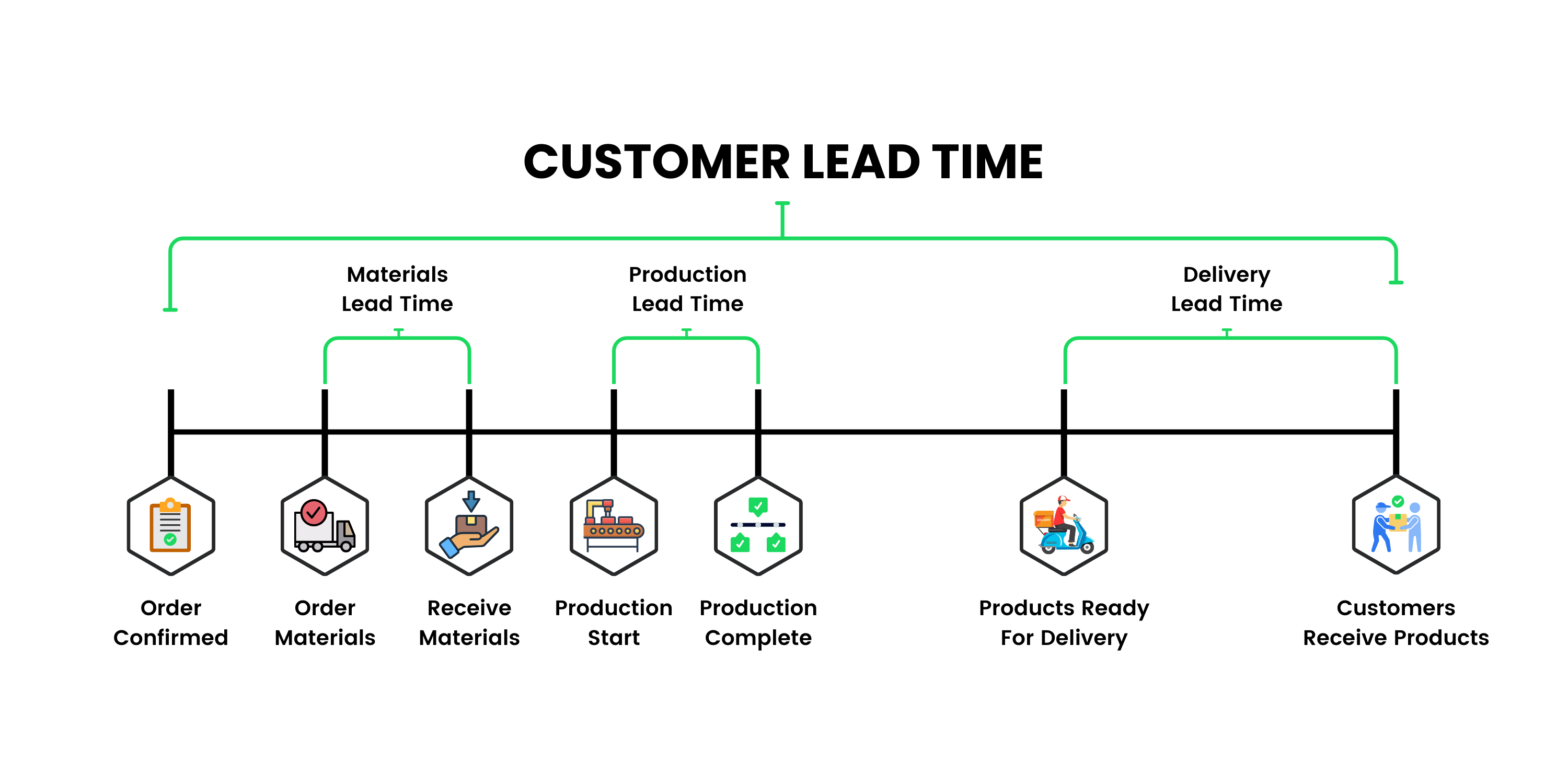

The quest to minimize lead time can be traced back to the origins of Just-In-Time (JIT) production, emphasizing the significant impact of bottlenecks and lot sizing. Lead time, with varied definitions based on process stages, essentially measures the time needed to complete an operation, calculated as the finish date minus the start date.

In supply chain management, total lead time is a crucial metric encompassing the period from customer order to delivery, be it in B2B or B2C scenarios.

This total time can be further categorized into key components:

Procurement Lead Time:

This dimension, situated in the upstream supply chain, covers the duration from placing an order to receiving it.

Production Lead Time:

Encompassing manufacturing, quality control, assembly, and related processes.

Delivery Lead Time:

In the downstream supply chain, delivery lead time represents the time from order receipt to product delivery, including activities such as packing and transportation.

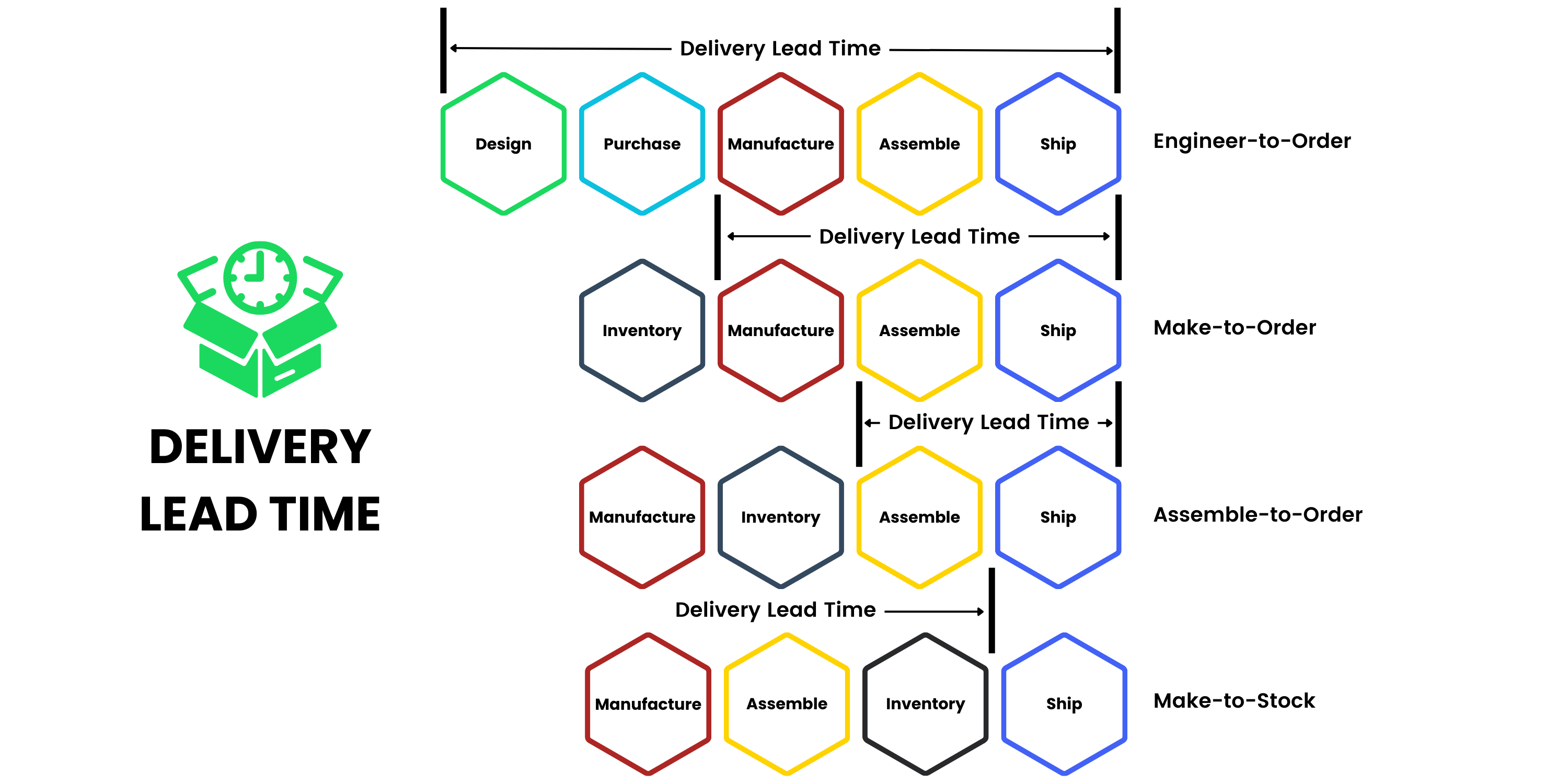

Depending on the chosen manufacturing strategy (Make to Stock, Assemble to Order, Make to Order, or Engineer to Order), the delivery lead time may vary as follows:

Access our blog “6 Reasons Why It Is Important to Understand Expected Customer Lead Time” at our website SCMDOJO!

Navigating the Impact: Uncontrolled Lead Time and Business Consequences

Uncontrolled lead time can have direct negative repercussions for a business, resulting in a lower service level, excess stock, increased variability, uncertainty, and additional costs. As a critical supply parameter, managing lead time is essential for mitigating uncertainties in the supply chain. According to the article “Modeling the flexibility of order quantities and lead-times in supply chains”, by Sanchoy K. Das and Layek Abdel-Malek : “most supply chains have only limited flexibility, and can only accommodate “noise” level uncertainties”.

Each type of lead time can impact the global process.

Procurement Lead Time:

- Efficient procurement lead time ensures timely access to raw materials, a fundamental step toward efficient production.

Production Lead Time:

- Beyond reducing carrying costs and inventory levels, an optimized production lead time empowers businesses to respond quickly to changes in market demand.

- The agility achieved through production lead time optimization serves as a strategic advantage in an ever-evolving business landscape.

Delivery Lead Time:

- Businesses must recognize the pivotal role of delivery lead time in shaping the overall customer experience and fostering brand loyalty.

Total Lead Time:

- The impact of lead time optimization extends to Return on Investment (ROI) and the general efficiency of the entire organization.

- An efficiently managed total lead time is a key factor for improved operational performance and sustained business growth.

Read more on “Optimizing Inventory and Lead Time Management” at our Website SCMDOJO!

Benefits of Lead Time Reduction:

Lead time reduction, which refers to the time it takes to complete a process from the initiation to the delivery of the final product, can offer various advantages to businesses. Here are some of the top benefits:

Improved Customer Satisfaction:

- Faster lead times mean quicker delivery to customers.

- Meeting or exceeding customer expectations for delivery times enhances customer satisfaction.

Increased Flexibility:

- Shorter lead times make it easier to adapt to changes in customer demand or market conditions.

- Businesses can more quickly adjust production schedules or change product offerings in response to market trends.

Reduced Inventory Levels:

- Shorter lead times enable businesses to maintain lower inventory levels.

- This can lead to cost savings by reducing the need for storage space, handling costs, and the risk of holding obsolete inventory.

Cost Savings:

- Reduction in inventory holding costs.

- Improved efficiency in production processes and resource utilization.

Competitive Advantage:

- Faster lead times can be a key differentiator in a competitive market.

- Customers often prefer businesses with quick and reliable delivery. Amazon has mastered this art, and everyone is trying to catch up!

Increased Cash Flow:

- With reduced inventory levels, capital is not tied up in excess stock.

- Faster turnaround times can also mean quicker payment cycles.

Improved Quality Control:

- Shorter lead times allow for more frequent quality checks throughout the production process.

- Defects can be identified and addressed earlier in the production cycle, improving overall product quality.

Enhanced Forecasting Accuracy:

- Shorter lead times make it easier to forecast demand accurately.

- Improved forecasting contributes to better overall supply chain planning.

Leaner Processes:

- Lead time reduction often involves streamlining and optimizing processes.

- The focus on efficiency can lead to the identification and elimination of waste in various stages of production.

Adaptability to Market Changes:

- Shorter lead times enable businesses to respond quickly to changes in market trends, customer preferences, or regulatory requirements.

- In simple terms, it makes your supply chain more agile to cope with market changes.

Innovation and Product Development:

- Reduced lead times can facilitate faster innovation and time-to-market for new products.

- Businesses can stay ahead of the competition by bringing new and improved products to market more quickly.

It’s important to note that the benefits of lead time reduction can vary based on the specific industry, product type, and the overall supply chain strategy of the business. Implementing lead time reduction strategies requires a careful analysis of existing processes and collaboration across different stages of the supply chain.

Mastering Lead Time: Stabilization and Optimization Strategies

The most common mistake is searching for how to reduce the lead time before trying to stabilize it. The journey to lead time reduction begins with understanding the existing lead time.

As part of effective supply chain management, it is important for companies to clearly distinguish between contractual lead time and actual lead time. Contractual lead time represents the agreed or expected period for the completion of a particular process, whereas actual lead time is the real-time taken to execute the process in practice. By identifying and analyzing the gap between contractual and actual lead times, companies can gain valuable insight into existing gaps. This awareness is the first step to identifying and resolving specific issues that may impact operational efficiency.

Once you have tracked your actual lead time, you need to stabilize it. Key steps in this process include:

Process Analysis:

- Conduct a thorough analysis of production and procurement processes to identify bottlenecks and inefficiencies.

- Targeted process improvements can lead to more efficient operations.

Supplier Transparency:

- Foster transparent communication with suppliers to anticipate delays and proactively address potential challenges.

- Collaborative relationships with suppliers contribute to a more agile and responsive supply chain.

Safety Stock Management:

- Maintain an optimal level of safety stock to mitigate variability and anticipate delays in the supply chain.

- Smart safety stock practices help protect against unexpected disruptions.

After this step, companies can take into consideration different actions to shorten it, such as:

Domestic Supplier Utilization:

- Engage domestic suppliers to significantly reduce lead times, especially in scenarios where overseas suppliers may involve extended delivery periods.

- Proximity to suppliers enhances the speed of material acquisition, accelerating the overall production process.

Onshoring for Enhanced Service:

- Consider proximity to class A customers to enhance customer service rates.

- Onshoring strategies contribute to a more responsive supply chain, aligning with customer-centric business approaches.

Optimized Order Frequency:

- While there’s a traditional belief that placing large bulk orders is a cost-effective strategy, it’s crucial to recognize that its suitability depends on the context: Large orders can indeed leverage economies of scale and optimize manufacturing costs, especially in industries where demand is relatively stable. However, it’s essential to consider potential drawbacks. These include increased carrying costs, the risk of product obsolescence with extended storage, and the need for substantial financial resources.

- Each industry and business scenario may require a tailored approach to order sizing. If possible, exploring the option of placing more orders could be beneficial in reducing lead times.

Vendor Managed Inventory (VMI):

- VMI is a collaborative approach to inventory management where the vendor or the supplier, usually the manufacturer, is responsible for replenishing the client’s stock.

- VMI acts as a bridge between the client and the supplier, allowing them to share real-time data. This visibility enables the vendor to actively manage the buyer’s inventory levels. Suppliers can anticipate demand and reduce replenishment times. This synchronization between supply and demand contributes directly to reducing the total lead time.

Consignment Inventory:

- Consignment Inventory is when the supplier stores inventory at the customer’s site.

- It contributes to reducing the lead time as the products are already available, thus eliminating ordering and shipping time.

Lean Manufacturing Principles:

- Lean manufacturing methods focus on continuous improvement and promote efficiency throughout the production chain.

- Implement lean manufacturing principles to eliminate wasteful activities and streamline production. By identifying and eliminating non-value-added activities, companies can optimize processes, reduce production cycle times, and ultimately minimize lead times.

As you may have noticed, although lead time is a classic parameter frequently discussed, taking effective action to stabilize and reduce it is no simple task. But if you master those points and act on them correctly, the consequences can be crucial. Not convinced? Let’s see some examples:

- By reducing its lead time, Zara succeeded in changing the design of its clothing every two weeks, compared to its competitors’ average of two to three months. This strategy allowed the Spanish label to triple its profits, expand its store network, and currently rank as the third-largest retailer.

- The fastest deliveries for Prime in the second quarter of 2023 helped Amazon capture a third of U.S. online orders, six times more than its biggest competitor Walmart.

- Dell, the market leader in the technology sector, has effectively managed lead times by relying on Just-in-Time Inventory Management.

Conclusion

In conclusion, understanding the importance of time in business is crucial. Efficient lead time management goes beyond a business necessity; it provides a strategic advantage in today’s competitive economy. Exploring the lead time definition becomes essential for navigating order fulfillment complexities and ensuring customer satisfaction. In this blog, we’ve delved into the definition of lead time, its impact on business, and how mastering it can be a competitive advantage.

By reducing lead time, businesses can experience benefits like improved customer satisfaction, increased flexibility, and cost savings. The journey to lead time reduction involves stabilizing processes, optimizing order frequency, and embracing lean manufacturing principles. In the end, mastering lead time is not a simple task, but the positive consequences can be transformative for businesses, as exemplified by success stories from Zara, Amazon, and Dell.

About the Author – Ikram Ahjiej

My name is Ikram Ahjiej. I studied Industrial Engineering at Ecole Nationale des Mines de Rabat. Currently, I am pursuing an Advanced Master’s in Global Supply Chain Management at KEDGE Business School, and I am apprenticing at Danone in Customer Service.

Frequently Asked Questions:

Q: What do you mean by lead time?

Ans: Lead time is the total duration from order initiation to completion, covering all intermediate steps.

Q: What is the meaning of time to lead?

Ans: It typically refers to the duration it takes for a company or product to establish a leading position in the market.

Q: Why is it called lead time?

Ans: The term likely comes from the idea that lead time precedes the actual delivery, providing an estimate for planning and execution.

Q: What is lead time vs delivery time?

Ans: Lead time includes the entire process duration, while delivery time specifically focuses on the duration between shipment and arrival at the destination.