Lean and Six Sigma are probably the most researched, published and utilized Continuous Improvement methodologies in Operations Management and Supply Chain. Lot of guys in my team are eager to learn both tools but they don’t always know which method and tools are applied in which problem scenario. I thought I should try to answer this problem scenario….

Get 5S – Kaizen Guide to Organize the Workplace for Flow

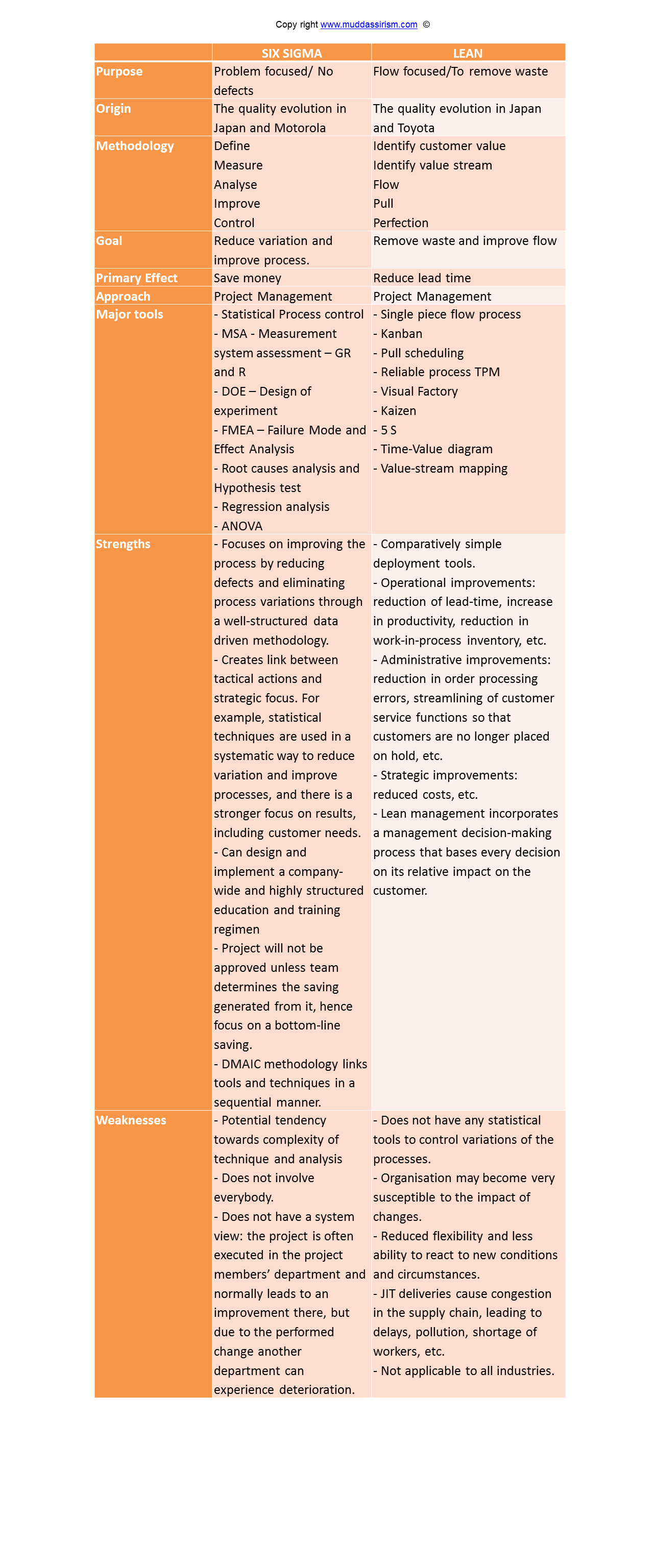

One way to look at how lean management and six sigma can complement each other is comparing the strengths and weaknesses of both, as shown in Table below, to understand their correlation. This Table identify the strengths and weakness for both lean and six sigma, highlight the fact that both philosophies complement each others’ strengths and weaknesses, address process variation reduction, waste reduction, reduction in non-value added work and cycle time at the same time . However, in the current literature it is still not clear how companies can systematically select and align Lean Six Sigma tools, or, in other words, what processes should companies adopt to systematically select and evaluate use of available CI methodologies to achieve the desired strategic or reactive goal link with their supply chain strategy? Hope fully below mentioned summary can help you with this.

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram