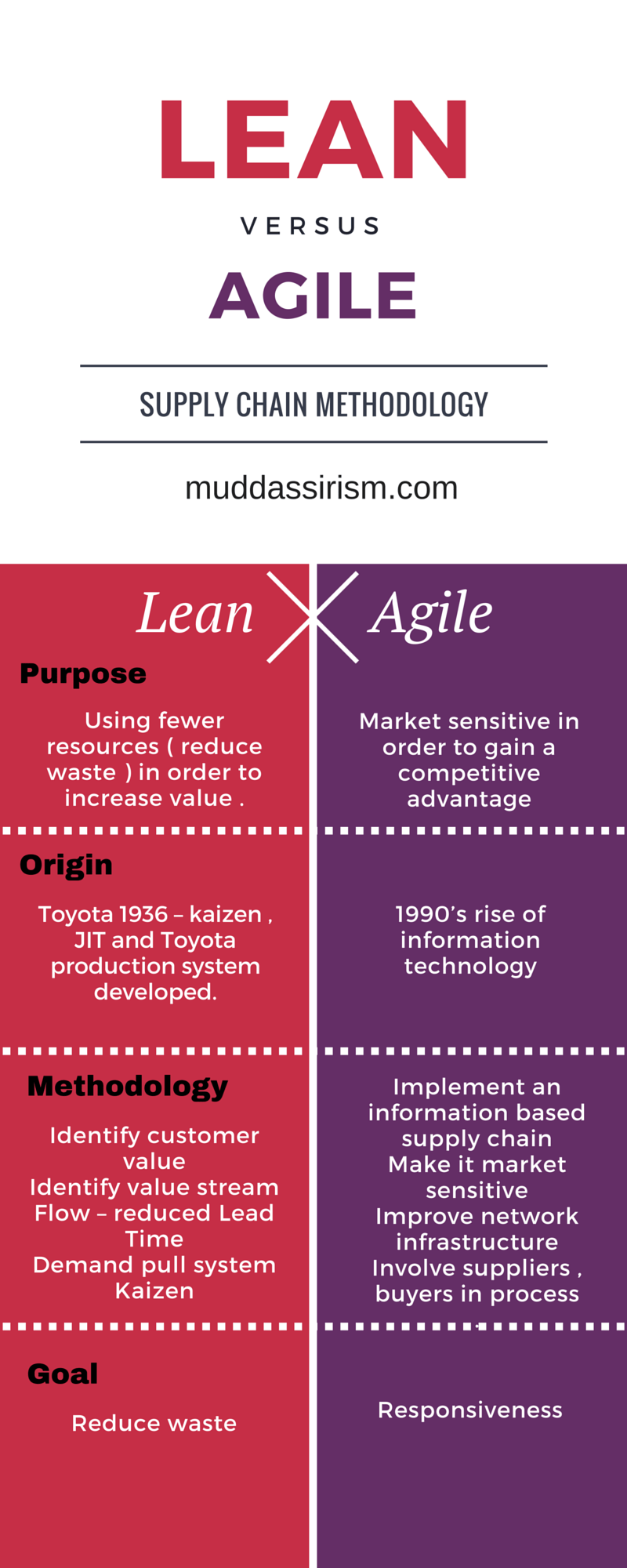

Lean vs. Agile Supply Chain – Can You Have One Without the Other? [Infographic]

Can you run an efficient manufacturing and supply chain organisation without any lean or continuous improvement tools? Can you grow your company and be more responsive without using any agile supply chain efforts?

Get 5S – Kaizen Guide to Organize the Workplace for Flow

It may come as a serious disappointment to you, but the answer to both is “not really” and “it really depends.”

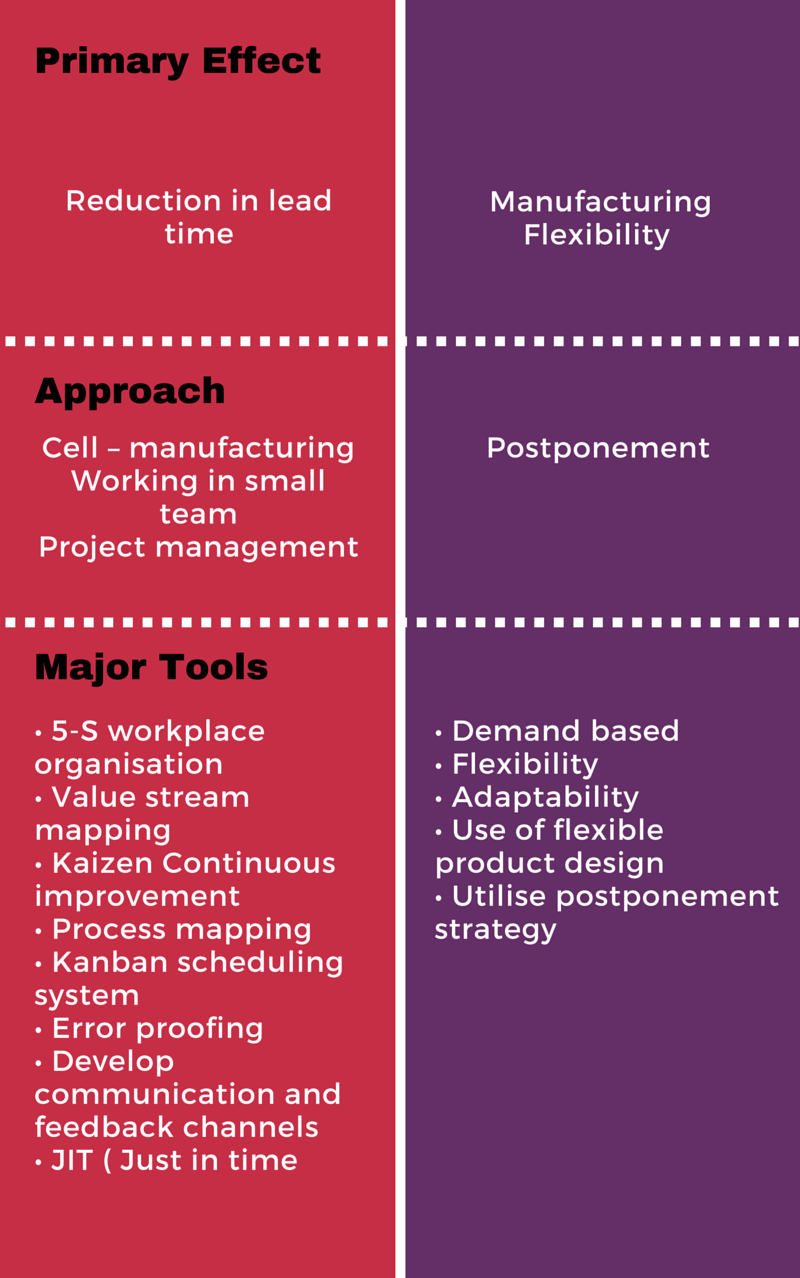

As always, there are always edge cases where a business can thrive using exclusively lean or agile supply chain efforts. However, for the vast majority of us, a sense of balance and combination of both is absolutely crucial. And here’s why as shown in this infographic:

How Can Lean and Agile Supply Chain Methodology Coexist?

Lean manufacturing focuses on the elimination of waste and is measured on cost reduction, productivity and other output based measures whereas agile focuses on meeting demand in volatile markets and performance is measured on customer satisfaction. Lean also focuses on stabilising demand over time with an emphasis on accurate forecasting whereas agile works in markets with a high demand variation in volatile markets.

Whereas agile focus on supply chain’s ability to react and adapt to the changes in demand and supply. From supply chain design perspective, few other fundamental differences in an agile supply chain is certain level of buffer are built into its processes, so that supply chain quickly respond to expected or unexpected changes. The agile supply chain need more flexible contract/arrangements with suppliers in terms of MOQs, firm planning windows and liability discussions. Whilst there are many good reasons for Single Sourcing, but in agile supply chain design it is advisable to have secondary supplier to cope with shorter lead time and/or sudden demand changes.

Another difference is in length of planning zones, in lean planning lead time tends to be longer, whilst organisation focus on short frequent suppliers using with JIT scheduling with a predictable markets (through forecasting), whereas in agile the demand tends to be unpredictable with a short lead-time hence, firm planning window are tend to very short.

With above apparently contradicting views Lean and agile supply chain can co-exist by utilising attributes mention in infographic presented in this blog. At the end of the day, the truth about lean and agile supply chain methodology working or not in practice is happy customer who get product on time, in right quality and at right price.

Implementation on macro scale

As with the Pareto 80:20 rule, the top 20% of products (SKU’s) which generates 80% of demand typically should be produced with the lean approach of production. This will include forecasting, managing inventory levels and economies of scale should be utilized.

The remaining 80% of products (SKU’s) which generate 20% of demand typically should then be produced with an agile approach, i.e. items being made on order, having highly adaptable components and styles of manufacturing that are versatile enough to the demand quickly.

Conclusion

While there is simply no easy or correct answer to the whole lean vs. agile supply chain methodology debate, it’s crucial for you to realize the following: at the end of the day, our job as supply chain community is to have happy customer who get product or service on time, in right quality and at right price.

No individual would ever attempt to argue the truism that supply chains are a remarkably complex species at most of the time. While I can’t answer the debate of lean vs. agile supply chain choice for your organization without additional business insights or data, the most likely answer is “use lean, but don’t ignore agile!” Purism is rarely the answer, and the world’s most intelligent supply chain professionals realize the value of nuance.

If you are looking for further details and information, I think you will find this slides very useful.

Are you running your business using purely lean or agile supply chain methodologies? Why or why not?

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram