Supplier Development Programme is one the key initiative in many large organisation and perceived as key driver to enable supply chain competitiveness. To understand this, lets briefly look into definition Supply Chain Management (SCM). Supply Chain Management was introduced in the early 1980s (Oliver and Webber, 1982) but it has only been growing in importance since the early 1990s. SCM is defined as the “integration of trading partners” key business processes from initial raw material extraction to the final or end customer, including all intermediate processing, transportation and storage activities and final sale to the end product customer” (Wisner, Tan and Leong, 2012).

Supply chain management is also defined as “the active management of supply chain activities and relationships in order to maximise customer value and achieve a sustainable competitive advantage” (Bozarth and Handfield, 2008). The importance of supply chain management has evolved in the last few decades due to stern competition in the market and due to the development in information and communication technologies, customers having access to the global markets (Chavhan, et al., 2012), making supply chain management an important tool for managing products or services from its raw to finished state and managing after sales services.

Supplier Integration

There is growing evidence in supply chain research that the higher the level of integration with supplier and customer in the supply chain, the greater the potential benefits. The answer probably lies in the fact that better co-ordination, reduction in uncertainty, waste reduction and reduction in variability leads to greater efficiency along with faster delivery performance. (Westbrook and Frohlich, 2001). Furthermore, integrated supply chains are enabling organisations to reduce inventory and costs, add product value, extend resources, accelerate time to market and retain customers. Therefore, in today’s dynamic and complex business environment, inter-firm business relationships are regarded as having huge implications for the firm’s business and competitiveness since an individual firm is no longer able to deal with the whole business operations without other under business relationships (Kato and Nunes, 2012).

As explained by Ellram et al., (2004) and Harland (1997), supply chain management is a process to combine the activities of suppliers, manufacturers and distributors so as to transform the raw material into finished goods and providing these to the consumer. In this process, the role of Supplier Development is considered to be significant, as without active and positive participation of supplier(s), it is difficult to develop a successful supply chain network (Chavhan, et al., 2012). To gain and maintain a competitive edge, companies strive to incorporate the activities of other partners of the supply chain. The level of integration in some organisations is high participating relationships, whereas in some other organisations, it is characterised by low involvement (Gadde, L.-E. and Håkansson, 2001). Integration can be virtual or vertical. In the case of virtual integration, there is a network or partnership and supply chain networks whereas, vertical integration is based on hierarchical solutions dealt by the ownership. Siems and Ratner (2003) suggested that the focus point of most of the organisations should be on core competencies, instead of producing goods and services where competencies of the organisations are not proficient, these should be outsourced. Consequently, the importance of network or virtual integration becomes more prominent.

Why Supplier Development Programme?

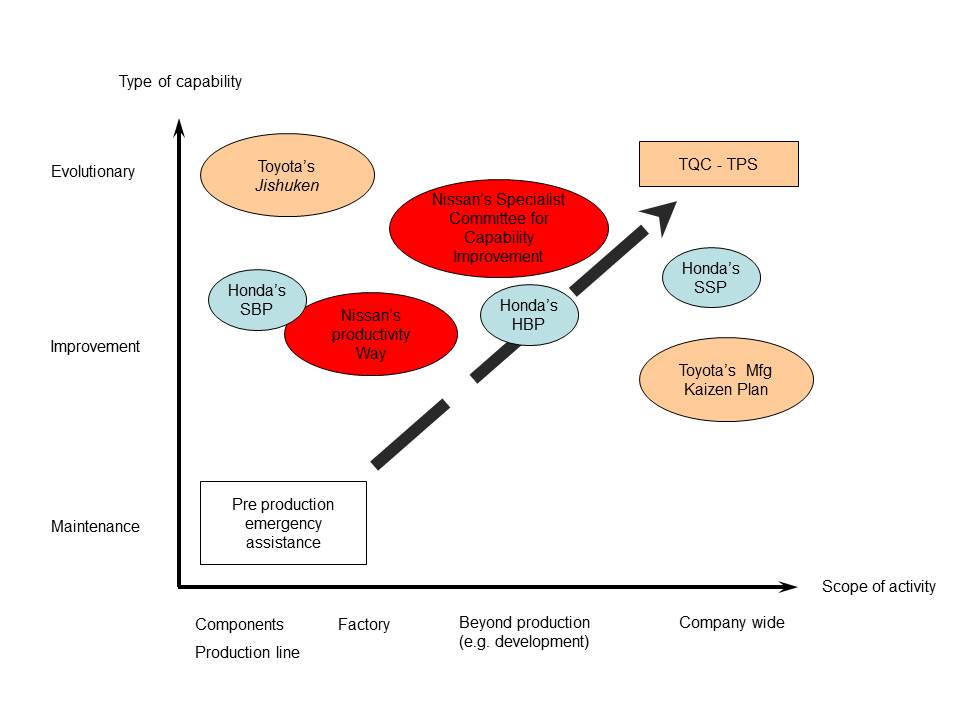

A number of studies confirmed several benefits of Supplier Development Programme activities (Hahn et al., 1990). Several firms practiced Supplier Development after recognising long-term and strategic advantages of Supplier Development. Supplier Development programme supported the suppliers to enhance their capabilities that ultimately improved the buyer performance (Kannan et.al., 2010). In the era of technological advancement and fierce competition where firms cannot produce all the goods and services required for manufacturing process, a good integration with other actors of the chain especially with the suppliers can provide a competitive advantage to the organisation for the long run. However, McIvor (2009) argues that neither vertical nor virtual integration in supply chain alone can fully explain the complexities of outsourcing, and that independent companies are better in some context than virtually integrated companies. Nevertheless, without improving the capabilities of the suppliers, it is challenging for the firm to sustain its competitive position in the market (Dyer, 1996). To establish long term relationship with the suppliers, firms need to develop skills and capabilities of the suppliers to match the requirement(s) of the organisation (Laugen et al., 2005); therefore, the Supplier Development Programme plays a vital role here. Interestingly, the concept of Supplier Development Programme is not new and we can find its origin in academic research from the last four decades.

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram