CENTRALIZE VS DECENTRALISE SUPPLY CHAIN PROCESSES

The debate to centralize or decentralize procurement processes is that organisations have been having for years; however, in supply chain processes context little has been written and said in my opinion (I did google it!). In recent years big organisations have observed a move towards centralized supply chain processes.

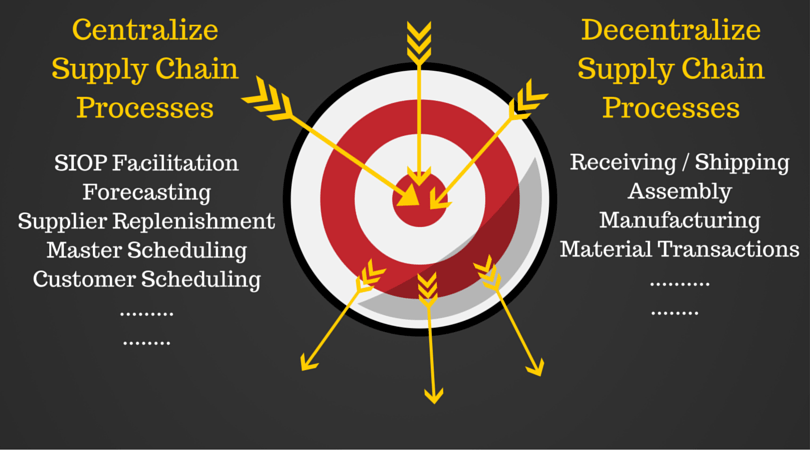

In this blog I have tried to explain my view of the benefits and drawbacks of a centralized approach, presenting similar perspective on decentralize approach of supply chain processes. Here, we look at arguments for and against and also some example of natural central processes and natural plant processes.

Centralize Supply Chain Processes

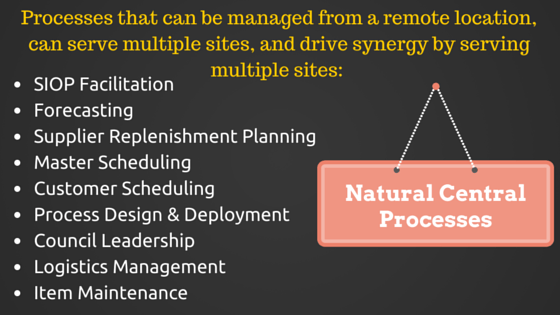

Centralize Supply Chain Processes are those that can be managed from a remote location, can serve multiple sites, and drive synergy by serving multiple sites. They provide for less duplication of resources and provide efficiency and effectiveness by managing key processes centrally. In some cases it can save money and bring economies of scale. Some examples of the example of centralize supply chain processes that can be managed centrally are shown in below image.

Advantages:

Processes like Sales Inventory & Operations Planning (SIOP) , Forecasting and Master Scheduling are pretty common in some organisations. By using appropriate tools demand forecasting can be aggregated from all sales subsidiaries and then distributed to the supply plants or warehouses to do rough cut capacity planning and materials requirement planning. By doing demand aggregation there is higher chances to reduce demand variation and bull whip effect in upstream of supply chain. In other example logistic management & its related spend can be managed centrally on a global level, by doing that companies can get bigger voice with the supply base. It also reduces duplication; more spend visibility and the ability to make the most of organizational spend.

We can also argue that centralize supply chain processes can improve moral in supply chain team and made better use of highly talented supply chain professionals. There is also a potential to maximize the total cost of ownership; the ability to better prepare for new product introduction and development; information in the items master maintenance should be reliable and up-to-date; and there is huge potential for targeted development of supply chain competencies.

Disadvantages

However, there are also drawbacks to central supply chain processes approach. There’s too much reliance on technology as opposed to human capital and skills, which could be disastrous as local knowledge is missing. To make it work the organisation requires heavy investment in information technology and systems which could be costly. This is supposed to reduce paper flow, but policies and procedure to make it work could potentially create more paperwork and red tape.

Other disadvantages potentially include too much power vested in one individual, innovation being stifled as supply chain processes become too prescriptive, and possibility it will take too long to identify systems errors and bugs!

Decentralize Supply Chain Processes

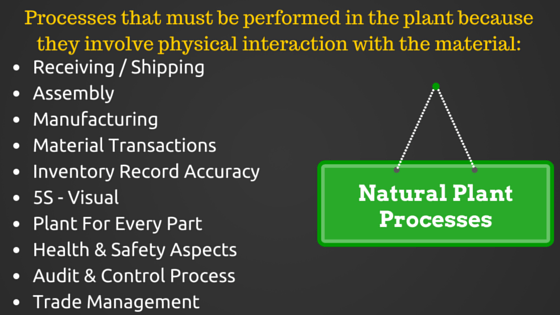

Decentralize supply chain processes can be defined as processes that must be performed in the plant because they involve physical interaction with the material. There processes are the ones where the decision-making is ‘localized’. It involves supply chain managers, planners, manufacturing teams, health and safety team and possibility trade management folks. Some examples of the example of centralize supply chain processes that can be managed centrally are shown in below image.

Advantages:

There are number of advantages of this approach, such as empowering employees, encouraging creativity and allowing many minds to work on the same problem. Speed of doing this is also a big advantage. Decision making process can be very quick and reflect local operating dynamics. For example receiving, shipping and assembly decisions there is shorter approval process when required, faster access to support and speedier replacement of defective material and quality issues, either product or processes quality.

Furthermore, there is no heavy investment is needed up front, managers are able to use first-hand knowledge and experience to improve their areas and there’s more accountability. Decentralize supply chain processes provide less bureaucratic with less power vested in one individual. Errors can be quickly rectified quickly & easily in items master. There is a reliance on human capital and associated skills as opposed to technical platform.

Disadvantages

In terms of disadvantages decentralize supply chain processes can result in duplication of effort in number of areas, longer planning cycles and create inefficiencies in key process. There is a danger than local buyers and planner will become paper pushers and/or expeditors with no real commercial or strategic experience & responsibilities.

Another big disadvantage is silo mentality which could become norm. There’s also the potential for corruptive practices, maverick approach to supply chain processes and mostly commonly master data can be compromised. Moreover, there is less preparedness for new product development and less utilization and development of talent pool.

Conclusion

Like most things in life there is no right or wrong answer to select which approach is correct and they most importantly Centralize or Decentralized approach are not mutually exclusive. In some cases, it might be worth considering hybrid approach to make the best of both worlds. For example, central origination can create set of policies and procedures for all plants and key strategic decisions are made centrally. And then it will pass on to plant to follow or adhered too.

If you have any questions about the Supply Chain Processes manage centrally or decentralize or have any experience applying it in your life or business, leave your thoughts in a comment below—I’d love to hear from you

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram