Companies are increasingly trying to achieve sustainability in supply chain management (SCM). The goal is to achieve sustainable flows of products, services, information and capital to provide maximum value to all corporate stakeholders.

The practices and structures of a globalized, capitalist world order gave rise to several challenges for corporations. Sustainable development is undoubtedly among the most important tasks to overcome in this new business world

There are several definitions of supply chain management when you Google it. Dictionary meaning of the term sustainability is “the ability to be maintained at a certain rate or level”. Or in simple terms, it’s endurance of system & processes.

The important factors in developing more sustainability in supply chain management are to identify the type of supply chain involved and the individual business attitude to extending responsibility for product quality into social and environmental performance within their own supply chain

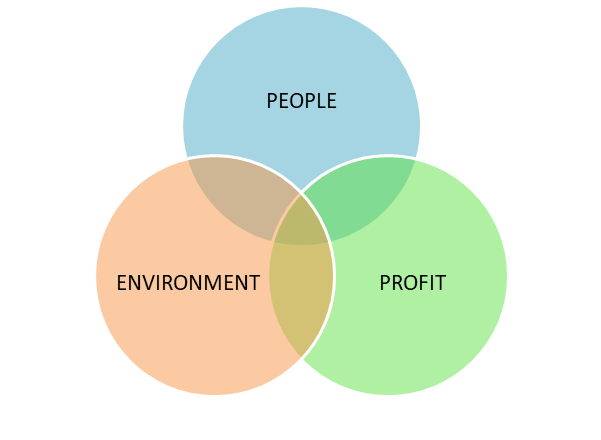

Now the supply chain main aim is to align with business strategy in which it operates and to align seamlessly need to have sustainability. Sustainability of supply chain is measured by 3 main factors as shown below image.

Best sustainability in supply chain management achieved (at a common portion of 3 circles above) when all 3 aspects (People, Profit, Environment) is achieved in right balance. If any one aspect is unbalancing then other two aspects go off center causing whole sustainability in supply chain management off center.

Now let’s see different areas to achieve sustainable supply chain in any organization. In my opinion following areas should achieve sustainability in the aspect of above 3 aspects to have perfect sustainable supply chain management.

Sustainability in Supply Chain Management – 5 Areas to Focus

1. Supplier Management (SRM)

Sustainable supplier relationship management has become crucial in companies’ efforts to achieve sustainability in supply chain management. A firm’s corporate image, in terms of economic, environmental and social behavior, heavily depends on its supply chain and the sustainability performance of each and every chain link, including suppliers and sub-suppliers.

Some of the leading companies in the world are intensively investing in Sustainable supplier relationship management practices in order to manage sustainability even beyond their corporate boundaries.

2. Product Design

Product design is the first step before actual birth or existence of the product in the real world. At this stage, every organization should give a deep thought to above 3 aspects (People, Profit, Environment) so better sustainability can be achieved.

Promoting sustainability within business operations requires sustainable products, processes, and system, i.e., sustainable supply chains. To efficiently reduce environmental and societal impacts of supply chains while maintaining continued profitability, it is necessary that the entire supply chain is designed and managed from a total life-cycle perspective considering coordination between product, process, and supply chain design.

Coordinating product and supply chain design decisions play a critical role in improving the sustainability in supply chain management. The product design determines all its future costs, both in forwarding and reverse-flow, which in turn depend on the supply chain configuration such as the number and location of supply chain partners their capabilities and capacities.

Therefore, coordinating sustainable product and supply chain design decisions requires consideration of all four product life-cycle stages and incorporating a closed-loop flow within the supply chain.

3. Process Design

Next stage after product design will be process design. Process planner at the organization should again think of process mapping with PPE approach so the outcome of the process will be sustainable. The organization should use innovative approach & use latest optimum latest technology to perform the process. What I meant by optimum technology is organization should not use unrequired hi-tech technology replacing human just for sake of automation.

Technology should be only used e to replace process which improves effectiveness & efficiency. This will take care of People aspect of sustainability.

Process design should be producing as less waste as possible which will take care of Environment as well Profit aspect of sustainability.

4. Operations

While designing sustainability in supply chain management from an operations perspective, it is important to consider aspects like:

- The Impact of Climate Change

- Demographic Evolution

- Urbanisation

- Emerging New Consumers

- Smart Technologies and the Digital Factory

- Sustainable Development and Corporate Social Responsibility

Furthermore, they are many reasons for driving sustainability in operations for example:

- Brand management

- Reputation

- Cost reduction opportunities

- Customer demand and lead time expectation

- Government regulation and compliance

- Shareholder expectations

5. Transportation

There is a very interesting article on “Sustainable transport: Is it the future of supply chain management? The article talks about smarter energy, smarter planning, and smarter driving.

Sustainability in transportation is high on agenda, however, according to MIT Research “Only a very small percentage of Fortune 500 companies have tried to significantly reduce greenhouse gas emissions from freight transportation in the supply chain through technological or operational tactics. These 22 companies are aggressively decreasing fuel use, switching loads to more environmentally friendly modes (i.e., forms of transportation such as rail), adopting technology to increase shipment efficiency and effectiveness and reducing shipment volume”.

This research clearly demonstrates how much work is required to achieve sustainability in supply chain management from the transportation perspective.

Summary

Environmental deterioration, growing concerns regarding climate change, and changing governmental rules and regulations introducing relatively new concepts is now a common industry challenge to archive sustainable supply chain management.

The challenge for organizations is to manage these challenges in above mentioned 5 areas of business and think how sustainability will be integrated into the supply chain processes.

Introducing sustainability in supply chain management initiatives is a result of some key drivers specific to your industry. In addition to the specific drivers of the sustainable supply chain, there are some industry-specific obstacles that create challenges for proper integration of eco-friendly systems to the respective supply chain processes. For example, the challenges belong to Automotive industry to achieve sustainable supply chain is very different from the food industry.

In order to analyze the industry-specific drivers and obstacles, we would recommend to start with above 5 areas and identify the basic opportunities to begin your journey.

This article is co-authored by

Uday is CSCP (Certified Supply Chain Professional) from APICS. He has worked in Indian as well as Australian power equipment industry for 22 years. ( Siemens and Toshiba). Uday holds a degree in Mechanical Engineering.

Recommended Readings:

Sustainable Logistics and Supply Chain Management: Principles and Practices for Sustainable Operations and Management

Developing Sustainable Supply Chains to Drive Value, Volume II: Management Issues, Insights, Concepts, and Tools-Implementation

Sustainable Supply Chains: A Research-Based Textbook on Operations and Strategy (Springer Series in Supply Chain Management)

A Focus on Sustainable Supply Chains and Green Logistics (Emerald Gems)

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram