Cycle Counting Procedure Guide

- 1 Files

- 732.37 KB

$40.00

The objective of this Cycle Counting Procedure is to establish guidelines and requirements for the implementation of Cycle Counting Programs across all business processes and sites.

The primary purpose of the Cycle Counting Program is to address discrepancies in quantities identified within warehouse stocks. These quantities are physically present within the warehouses. The Cycle Counting procedure is recommended to enhance the effectiveness of audits and minimize the challenges associated with physical counting.

Cycle Counting Procedure Benefits Upon Implementation:

- Upon implementation, this Cycle Counting procedure addresses the root causes of inventory discrepancies and promptly takes corrective actions to mitigate or reduce future occurrences.

- Businesses often favor Cycle Counting over physical inventory counts due to their reduced disruption of daily operations, ongoing assessment of inventory accuracy, and adaptability to various items.

- Frequent cycle counting reduces the intervals between physical counts for specific items. This approach facilitates the identification of opportunities to thoroughly diagnose the causes of discrepancies and to provide guidance on rectifying human errors before systemic issues emerge.

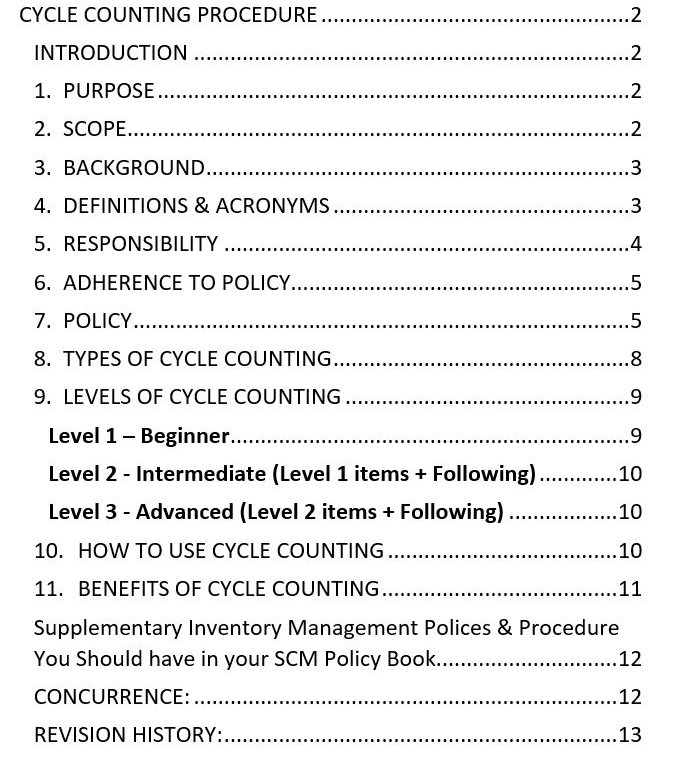

The cycle counting procedure comprises 13 pages with a word count of 3027. It is available in both Microsoft Word and PDF formats, enabling you to tailor it to your own business needs.

This Cycle Counting Procedure will aid in defining key criteria, such as the frequency of counting high-valued items based on their value, acceptable loss criteria, or the level of focus required in areas where inventory management issues have been identified.

Benefits of the Cycle Counting Program

Traditionally, organizations would often halt operations during stock-taking periods to ensure completion within the shortest time frame possible. This consideration entails timing considerations that affect trading and result in overtime expenses. However, this program resolves numerous such challenges and additionally provides the following cycle counting benefits:

- Accurate and Informed Decision-Making.

- Assistance with Distribution, Production, and Stocking Decisions.

- Enhanced Customer Services.

- Minimal Staff Disruption.

- Reduced Process Disruptions.

- Expedited Corrective Actions.

You can further reap benefits by exploring “Stocktaking: The Ultimate Guide (Stocktaking Procedure).”

If your country does not have PayPal, you can download it from this Gumorad link.

Access our Best Practices on our Website!

Indirect Procurement Best Practices Assessment

Distribution Operations Assessment Tool

Supply Chain Digitalization Assessment

Logistics KPI Dashboard Excel Template

Ratings and Reviews

What's your experience? We'd love to know!

Write a ReviewThere are no reviews yet. Be the first one to write one.

No reviews found.

- Upgrade to

Pro plan to avail more discounts and perks - Unlimited access, anywhere, anytime

- Single-User License

- One-Time Payment

- Instant Download

Files Included

| 1 | Cycle Counting Procedure | 732.37 KB |

| 732.37 KB |