Machine Learning Forecasting is attracting an essential role in several significant data initiatives today. Year ago, I have mentioned machine learning as top 7 future trends in supply chain. Big retailers, Supply chain, and logistics experts are using Machine Learning Forecasting to aid improve customer engagement and produce more precise demand forecasts better than traditional forecasting techniques. In addition to that, the concept of forecasting is taken up by a lot of institutes which provide machine learning course to aspirants. This incorporation has propelled a lot of deserving candidates to do good in the niche where they are in. They can also use Machine Learning Forecasting to expand into new sales channels, improve customer service, reduce inventory and improve productivity.

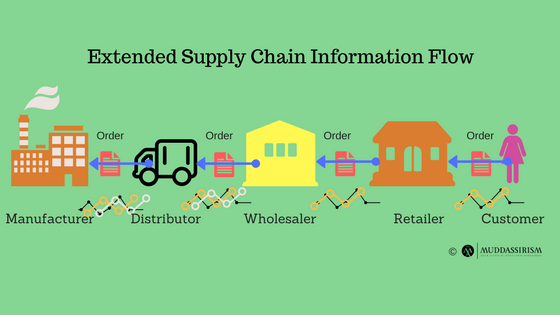

There are many good reasons why demand forecasting is important. However, putting a reliable forecast for any business is collaborative efforts sharing across the supply chain with distorted demand signals, as demonstrated in the picture below. According to Premkumar (2000) Therefore could be a number of factors which could hinder successful supply chain collaboration, like:

- “alignment of business interest

- long-term business relationship management

- reluctance to share information

- complexity of large-scale supply chain management

- competence of personnel supporting supply chain management

- performance measurement and incentive systems to support supply chain management”

Get The Ultimate Guide to Demand Forecasting

Therefore, a business must continue to find a way to improve forecasting accuracy.

Machine Learning Forecasting is certainly the method to achieve high forecast accuracy and way forward. With Machine Learning Forecasting, processors learn from mining loads of big data without human interference to deliver unparalleled customer demand insights. Extrapolative analytics and algorithms, like Neural Networks (NN), Recurrent Neural Networks (RNN), and Support Vector Machines (SVM) have developed as the latest discussion amongst senior managerial sides. Machine Learning Forecasting is self-correcting and powerful if compared with traditional forecasting techniques like average, moving average, trend, multiple linear regression.

Recently I have come across a company Vekia, who is a pioneer of Machine Learning in the Retail supply chain, and help Retailers optimize their inventory management, automate their processes (make them more reliable and more efficient) and be more agile (make the most of their current Supply Chain and adapt it quickly). They are experts at helping retailers to optimize store supply and provide predictive sales forecasts, with up to 97% accuracy, and we guarantee 5-10% productivity gains. So, if you are looking for Sales Forecasting Optimisation/ Demand Forecasting using Machine Learning, Vekia is the great team to connect with.

For years, Machine Learning Forecasting models have been rejected due to the absence of storing and processing abilities essential to engaging them. Nowadays, with cloud computing, dynamic regression, and unnoticed machinery, models are turning into the catalyst for “Machine Learning Forecasting.” With the use of pattern recognition, there will be a swing from vigorous engagement to automatic engagement. As part of this shift, Machine Learning Forecasting takes over tasks from info gathering to real implementation. Compared to traditional forecasting techniques, Machine Learning Forecasting Aids Supply chain and logistics experts recognize and forecast consumer demand that, in most scenarios, would be otherwise impossible.

Here are five (5) reasons why machine learning forecasting is better than traditional forecasting techniques:

-

Imperfect vs. Perfect Data and Info

Traditional forecasting techniques are founded on time-series forecasting approaches that can only use a few demand factors. On the other hand, Machine Learning Forecasting combines big data, cloud computing, and learning algorithms to evaluate millions of information using limitless amounts of fundamental factors at once. And this can apply to up and down a firm’s business pecking order. Traditional forecasting techniques are limited to only the available demand history, while Machine Learning Forecasting can take advantage of unlimited data, defining what is important, then line up available customer insights to stimulate future demand with the use of “what if” analysis. Compared to Traditional forecasting techniques, Machine Learning Forecasting solutions recognize the fundamental demand drivers that impact demand, exposing insights not conceivable with Traditional forecasting techniques. Besides, the self-learning algorithms get shrewder as they munch up newer data and become accustomed to the processes of consumer demand.

-

Holistic Models Using Several Scopes Against Sole Dimension Algorithms.

Traditional forecasting techniques are branded to have some sole dimension algorithms, individually planned to evaluate demand based on some particular data-limited restraints. As a result, many manual manipulations go into cleaning data and unscrambling it into the baseline and endorsed capacities. This restricts which set of rules can be used amongst the brand’s collection. Machine Learning Forecasting can give the impression of a “black box” where even a more precise estimate is regarded with uncertainty when the difficulty of the predicting model resists pure enlightenment. The output of Machine Learning Forecasting provides relative importance of several data sources with data reputation understandings improving interpretation. It also makes available relevant feedback on what data can enhance value and which should be observed for future use.

[button url=https://www.udemy.com/course/forecast-anything-with-excel/?LSNPUBID=cENl5ItFhTQ&ranEAID=cENl5ItFhTQ&ranMID=39197&ranSiteID=cENl5ItFhTQ-i4z6oUucJ04VhQAiwf2Sig size=16 icon_size=32]Learn Forecast Anything with Excel[/button]

-

Machine Learning Forecasting Takes a Classier Approach.

It makes use of pattern identification with a separate, wide-ranging array of algorithms that become accustomed to all the data. They are suitable for several categories of demand forms. Additionally, they occur simultaneously across the brand’s portfolio down/up the firm’s business pecking order without data cleaning of several data sources in the same model. For instance, Traditional forecasting techniques have a formal resolution leading to several unpredictable forecasts across the brand portfolio. With Machine Learning Forecasting, the similar algorithm is beneficial for several methods including advertising, in-store merchandising, sales promotions, store inventory, temperature, valuing, and others producing one idea of a well-combined forecast.

-

More Data – Better Accuracy

Typical forecasting approaches project impending sales from previous sales heights; seasonality and recurring tendencies are mixed, but brand features, value, rebates, and sales channel info are often overlooked during predicting and are later accounted for in other alterations. Machine Learning Forecasting allow for more data to be fused into the forecast. The forecast is augmented at the level of the distinct product, including what is known about evaluating history, rebates, and other issues that may be under administrative control. Product elements, wrapping, raw material valuing, third-party fiscal data, and practically anything that can be counted can be fused into the prediction.

-

Limited vs. the Whole Use of Item History.

When making demand forecasts, Traditional forecasting techniques evaluate the demand history for a particular product, group, station, and demographic buying area. Machine Learning Forecasting controls the history of all products, together with sales advancements, and estimated demand. For each product at every stage in the corporate pecking order, they make use of contemporary forecasting techniques. Some prominent retailers, Supply chain, and logistics experts believe the subsequent generation of Machine Learning Forecasting will also consist of cognitive computing where the whole process turns out to be self-healing. This would expand rapidly as Machine Learning Forecasting by going past estimates to taking verdicts on how to inevitably correct for glitches in the prediction process.

CONCLUSION

Creating forecasts at any level may seem to be exhaustive, and there is some truth to that. But Machine Learning Forecasting has been technologically advanced to capitalize on the equivalent processing abilities of contemporary PC, resulting in super-fast forecast results. Well, look no further as Machine Learning Forecasting is the future of demand administration. These advancements are in total support and line with the upcoming generation. Big retailers, Supply chain, and logistics experts will eventually need to recognize cognitive learning in generating an autonomic self-sustaining forecasting process. These techniques can advance precision and do not have any difficulty to implement, something to put in consideration as you plan towards the future.

So what forecasting techniques you have been using which has worked for you? And why you would not try machine learning forecasting? Please share your thoughts

Reference:

Premkumar, G.P., 2000. Interorganization systems and supply chain management: An information processing perspective. Information Systems Management 17 (3), 56–69.

Best Plagiarism Checker & Proofreader

Recommended Reading:

Machine Learning for Absolute Beginners: A Plain English Introduction

Hands-On Machine Learning with Scikit-Learn and TensorFlow: Concepts, Tools, and Techniques to Build Intelligent Systems

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram