If the businesses want the functions of their supply chain to be optimized or achieve supply chain optimization, it is not sufficient to simply select a correct strategy. They rather need to analyze their weaknesses and strengths, for improving the demand chains in terms of measuring their overall performances. Hence, the potential failures can be corrected and adjusted, while success factors can be reinforced (Matson, 2009).

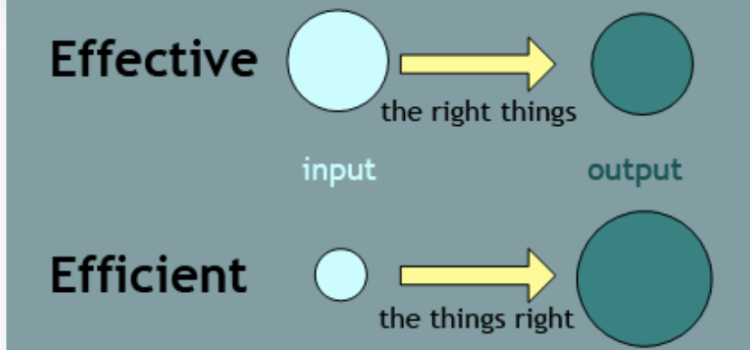

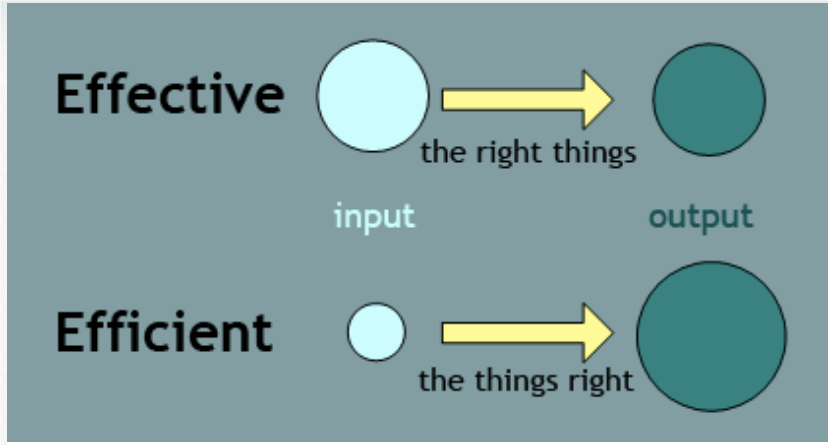

“It is a manager´s job to be efficient and do something the right way, but it is theexecutive´s job to be effective do the right thing” (Drucker, 1994)

That again will affect their efficiency as well as effectiveness, in which these factors can be measured, analyzed and optimized (Gunasekaran, et al., 2004); (Ostby, 2009). Cooper, et al., (2014) argued that alongside product quality, delivery integrity is essential for the customers, which is only achievable through an effective supply chain performance. Therefore, establishing partnerships with the sub-tier suppliers is pivotal.

It assists in saving costs, by identifying the logistical strengths and weaknesses. For that purpose, all aspects, entities and processes along the value chain need to be involved. In performance measurement process no element should be singled out and also for non-existing and potential problems that could eventuate, solutions should be planned in advance (Gunasekaran, et al., 2004); (Zokaei & Hines, 2007).

Effectiveness vs. Efficiency in Supply Chain Optimization

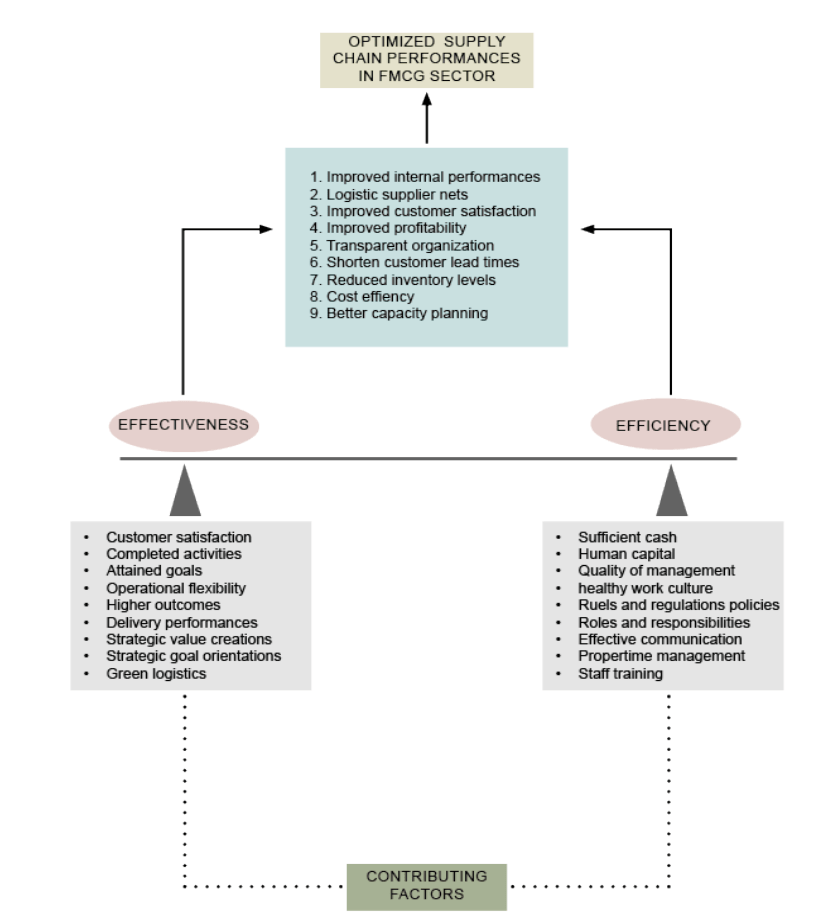

Here, the two-dimensional performance management is composed of efficiency and effectiveness that serve as a valid basis, as in agreement with Sahay, (2003). However, balancing these factors in other to achieve supply chain optimization appears to be the cause for potential complications and challenges for many organizations. The businesses are primarily overemphasized and obsessed on augmenting efficiency, and thus fail to achieve differentiation and innovation due to neglecting effectiveness as per Mouzas, (2006); Zokaei & Hines, (2007). In this context, Rosenfeld, (2013) stresses out that

“any attempt to improve efficiency, without an equal emphasis on effectiveness, is likely to be counterproductive”.

Borgström, (2005); Morse, (2016) explains that efficiency is associated with internal performances, especially when it comes to manufacturing and “doing the things right”, whereas Mouzas, (2006) relates it to the fundamental driver for operating margins, productivity, and operational excellence evaluation.

According to an insightful analysis of Henandez, (2012); Balocco, et al., (2011), efficiency strives to maximize the output with the minimum input. Hence, it can be achieved by reducing costs, outsourcing and underfunding promotional and research activities contributing to supply chain optimization.

The input resources might be of financial, material, human, technological or physical components (Holweg & Bicheno, 2002). Further, efficiency can be related to qualitative as well as quantitative parameters for supply chain evaluation, which is a “value-free” quantifiable indicator for improving processes (Borgström, 2005). It is regarded as a short-term objective (Mouzas, 2006). Therefore, beyond product management, the entire SCM should be managed effectively as suggested by Zokaei & Hines, (2007).

Mouzas, (2006) assigns effectivity to the ability to generate sustainable operational growth in earnings through networking, measuring achievements of intended objectives to actual outcomes. Ergo, the value chain is composed of a combination of suppliers and their networks, as per Borgström, (2005).

Effectiveness vs. Efficiency (Henandez, 2012).

To sum up, the main differences between these two elements is that efficiency is concerned with all related resource and process input minimization, while effectiveness aims to attain all goals, higher outcomes, completed activities and increased customer satisfaction, by being as customer and goal oriented as possible, Hence achieving supply chain optimization.

Six Sigma Green Belt Certification Training

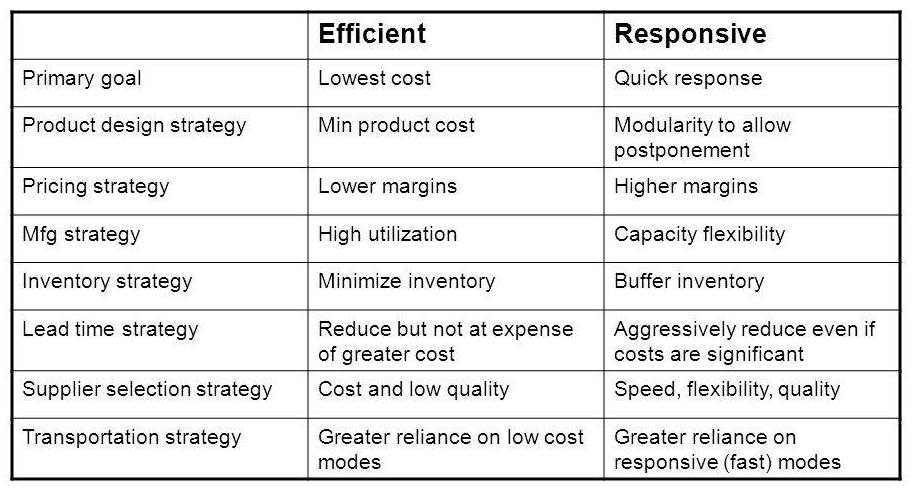

Comparison of Efficient vs. Responsive (Effective) Supply Chain

Below image identifies the specifications and variances of responsiveness and efficiency and comes to the following collation:

Comparison of Efficient vs. Responsive (Effective) Supply Chain

It is clarified that while efficiency is the highest attempt to reduce all resources, by the maximum usage of all capacities, responsiveness endeavors to be as flexible and customer oriented as possible. Even if the term “responsive” instead of “effective” is used in the comparative scheme, there is no distinction in their nature and meaning as confirmed by Pitagorsky, (2013). Hence, in order to be effective, there is a requirement of being responsive, which has to be considered as a short as well as long-term objective of the businesses (Pitagorsky, 2013) goal of supply chain optimization.

Govil & Proth, (2002); Hugos, (2011) point out that efficiency and effectiveness can improve supply chain performance through intensified collaboration with all relevant participants. For instance, it makes all partners in the value chain equally empowered, valued, given responsibility and if necessary, supplemented in order of achieving the maximal degree of performance.

As this takes place, all parties need to be integrated and informed timely for improving their performances in other to achieve supply chain optimization. Especially when demand and progression strengthens. Internal as well as external incorporation results in a better appraisal of return of investments in SCM at all levels.

In order to amplify the extent of effectiveness in optimizing proposes, Mouzas, (2006) recommends emphasizing on advantages through value appreciation for the customers, instead of developing expansion strategies. Hence, effectiveness plays a significant role in supply chain optimization by aiming to achieve all targets, higher outcomes, completed activities, increased customer satisfaction, etc. (Fisher, et al., 1994).

When it comes to supplier´s effectiveness, they have to be able to be flexible and agile in terms of covering customer´s requests, needs and wants, regardless of their capacity, capability, warehouse management, etc. Thus, when they cannot supply as requested, it results in being ineffective (Borgström, 2005).

On the other hand, the advantages of using efficiency for the purpose of optimizing overall performance can lead to lean production, packaging, material management, waste, and energy reduction, logistic supplier nets, etc. It assesses operational productivity from a resource dependence perspective, whereby the output produced should be equivalent to the profit, as hinted by Borgström, (2005); Mouzas, (2006).

In essence, an efficiency is a suitable tool, as it backs up the traditional cost minimization approach in supply chain optimization of performance as explained Johnson, (2011); Lee, et al., (1997).

In terms of SCM, the theoretical construct of efficiency and effectiveness are interdependent yet inextricably interrelated. They act as the interplay between the markets and organizations.

According to an empirical study by Sarac, et al., (2010); Cecere, (2014), the most efficient supply chain is not effective; a fact that makes it hard to equilibrate these two elements.

The balance between Efficiency & Effectiveness (Own Creation 2016) to achieve supply chain optimization

Conclusion

As stated in the literature review, effectiveness and efficiency are the key drivers for a supply chain optimization, excellent supply chain performance, processes, and strategies. They assist in goal attainment in various areas, being procurement, sales, distribution, logistics, warehousing, etc. It is therefore particularly significant to integrate all departments in order to have a holistic perspective and a synchronizing and cooperating supply chain. I

In order to enhance effectiveness, the companies need to strive for innovation maximization in all possible realms, by building partnerships along the value chains. This again would enable them to gain access to external resources (Sarac, et al., 2010).

Mouzas, (2006) accentuated that having an equal level of efficiency and effectiveness leads to supply chain optimization. However, at the same time he claims that this ideal situation in the business environment does not exist. Due to this reason, it is pivotal to pay equal attention to both elements, since any attempt to improve efficiency, without an equal emphasis on effectiveness, is likely to be counterproductive” (Rosenfeld, 2013).

If you have any thoughts on supply chain optimization or this article please do share in the comments below.

About Author: Sinbl Hawro Yakoob

Sinbl graduated in Int. Business Studies, specializing in Supply Chain Management (SCM), from the Zuyd University of Applied Sciences in Maastricht, NL. In 2016 Single has finalized Masters in Int. SCM and Logistics at the Plymouth University, GB. Hence, she endeavored an academic career within multiple countries, in order to learn different facets of Logistics and SCM. While studying International Business, the subjects of Logistics and SCM have enhanced her interests considerably, and therefore she has decided to pursue masters in that field. Having a profound insight in this realm is significantly contributing and instilling to her knowledge, which is certainly pivotal for being able to write articles and transfer this know-how for the interested readers. Thus, combined with Sinbl’s interest in international development, she is positive that she has much to add to this blog and for its followers. Currently, Sinbl is working at Mercedes Benz Customer Assistant Center Maastricht, NL in the Partner Network Management, in which she is responsible for Certification Management. You can connect Sinbl on Linkedin.

Recommended Reading

[button url=https://www.amazon.com/shop/dr.muddassirahmed size=15 icon=heart-2 icon_size=32]Visit My influencer page on Amazon[/button]

Total Value Optimization: Transforming Your Global Supply Chain Into a Competitive Weapon

Supply Chain Network Design: Understanding the Optimization behind Supply Chain Design Projects

List of References

- Balocco, R., Miragliotta, G., Perego, A. & Tumino, A., 2011. RFId adoption in the FMCG supply chain: an interpretative framework. SCM: An Int. Journal, 16(5), pp. 299 – 315.

- Borgström, B., 2005. Exploring efficiency and effectiveness in the supply chain; A conceptual analysis. pp. 1-11.

- Cecere, L., 2014. The Most Efficient Supply Chain Is Not the Most Effective. DOIt: http://www.forbes.com/sites/loracecere/2014/03/10/the-most-efficient-supply-chain-is-notthe-most-effective/#1dcf82d072fa[Accessed 30 05 2016].

- Cooper, M. C., Lambert, D. M. & Pagh, J. D., 2014. Supply Chain Management: More Than a New Name for Logistics. The Int. Journal of Logistics Management, 25(3), pp. 1-14.

- Drucker, P. F., 1994. The Effective Executive: The Definitive Guide to Getting the Right Things Done. s.l.:HarperBusiness;

- Gunasekaran, A., Patel, C. & McGaughey, R. E., 2004. A framework for supply chain performance measurement. Int. Journal of Production Economics, 18 02, pp. 333-347.

- Henandez, J. G., 2012. Efficency and Effectiveness. DOI: http://jesusgilhernandez.com/2012/10/15/effectiveness-and-efficiency / [Accessed 30 05 2016].

- Holweg, M. & Bicheno, J., 2002. Supply Chain Simulation – A Tool for Education, Enhancement and Endeavour. Int Journal of Production Economics, 78(2), pp. 163-175.

- Lee, H. L., Padmanabhan, V. & Whang, S., 1997. Information Distortion in a Supply Chain: The Bullwhip Effect. The Institute of Management Sciences, 43(4), pp. 1875-1886.

- Matson, J., 2009. Cash is king: improving working capital. SCM Review, 13(3), pp. 28-32.

- Morse, A., 2016. Supply Chain Efficiency vs. Effectiveness. DOI: https://www.handshake.com/blog/supply-chain-efficiency-vs-effectiveness/ [Accessed 30 05 2016].

- Mouzas, S., 2006. Efficiency versus effectiveness in business networks. Journal of Business Research, 01 12, p. 1124–1132.

- Ostby, I., 2009. Supply chain for the greater good: discover how supply chain professionals are using their industry skills for good causes. APICS, 19(5), pp. 36-39.

- Pitagorsky, G., 2013. To Be Effective Be Responsive, Not Reactive. DOI: https://www.projecttimes.com/george-pitagorsky/to-be-effective-be-responsive-not-reactive.html [Accessed 24 06 2016].

- Rosenfeld, M., 2013. Audit Efficiency and Effectiveness. DOI; http://de.slideshare.net/MannyRosenfeldCIAMBA/audit-efficiency-and-effectiveness [Accessed 23 07 2016].

- Sarac, A., Absi, N. & Dauzère-Pérès, S., 2010. A literature review on the impact of RFID technologies on SCM. Int. Journal of Production Economics, 128(1), pp. 77-95.

- Zokaei, K. & Hines, P. A., 2007. Achieving consumer focus in supply chains Article. International Journal of Physical Distribution & Logistics Management, 37(3), pp. 223-247.

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram