Nobody could disagree that the present distinction between S&OP (Sales and Operations Planning) and IBP (Integrated Business Planning) has long been the subject of important and fascinating discussions within the economic context. There are now two castes of opinions: There are some supply chain experts who contend that there is no distinction between the two ideas, while there are others who disagree. In this blog we will be looking further into this discourse and evaluate the difference between S&OP vs IBP.

Oliver Wight’s investigations lead us to the conclusion that IBP looks to be a more developed stage of S&OP, indicating that IBP can be thought of as an extension or expansion of S&OP. According to Oliver Wight, IBP is a set of interconnected and interacting actions that the Top Management uses to continuously manage to focus and align all organizational functions. This suggests that the IBP is a later, more developed stage of the S&OP.

Why compare it in the first place if it is that simple?

We must acknowledge that the S&OP process has run its course in the current economic environment. To balance the supply and demand chains is where it is most frequently applied. While it does address some financial issues, a full financial prognosis for the future is not covered.

To delve deeper into the technicalities, let us first go over the definitions of S&OP and IBP.

Definition of S&OP (Sales & Operations Planning)

S&OP is a procedure that can assist you in providing better customer service, less inventory, shorter lead times, more consistent production rates, improved management control of the total organization, and a mechanism for team development across the entire senior management organization.

It is a cross-functional planning procedure intended to maintain supply and demand equilibrium. This is accomplished by regularly communicating with the internal organization about changes in the external market demand (via the sales department). To make the best possible purchasing (Inventory) and production (Operations) planning decisions, staff in the Supply Chain, Finance, and Production departments use this data.

Mature S&OP:

- Is on the board’s agenda.

- Is a ‘business management method’ that integrates demand, supply, and financial planning

- It promotes actions that bridge the gap between your goals and the realities of doing business.

- Plans to fulfill management commitment in an open manner.

- Implements the business plan at all organizational levels and ensures its stability.

I have meticulously crafted an on-demand S&OP course tailored for supply chain practitioners. This comprehensive course elucidates the significance of S&OP, delineates its five-step process, explores its benefits, and delves into real-world deployment challenges using illustrative examples.

Definition of IBP (Integrated Business Planning)

There are various definitions of IBP, but techtarget’s is the one I like most.

“Integrated business planning (IBP) is a strategy for connecting the planning functions of each department in an organization to align operations and strategy with the organization’s financial performance.

An effective IBP strategy can help sales and operations balance supply and demand, give human resource (HR) managers the right clues about hiring and training and provide the Chief Financial Officer (CFO) and other C-level administrators with a more comprehensive view of each department’s goals so that areas of overlap can be identified and the company can maintain a sustainable competitive advantage. An important goal of every IBP initiative is to help each department within the organization make informed decisions about product-market strategy, including new product introductions and capital investments”

Driving Growth and Efficiency with S&OP vs IBP Processes

S&OP Characteristics

- Offers a balance between supply and demand

- Promotes proactive decision-making

- Formalizes business communication processes.

- Enhances the integration of various functions.

- Makes it possible for an ecosystem to be informed and unified (from the supplier’s supplier to the customer’s customer).

- Is essential to providing an agile response to demand.

- Is the primary layer of integration for total value optimization.

- Delivers the proper product at the proper time, place, quantity, cost, and level of company performance.

- Provides security, encouragement, and drive to achieve tangible advantages.

The Top Management will be able to coordinate numerous scheduled actions in the organisation through the S&OP. The creation of a thorough business plan that incorporates multiple functional planning activities would be its main objective. As a result, the company could fail if S&OP is not integrated and operates at a cross-functional level.

IBP Characteristics:

- Assists in the profitable distribution of essential resources (people, machinery, supplies, inventory, time, and money) to best satisfy client needs.

- Ensure that any possible performance gaps in the business are promptly addressed.

- Delivers exceptional long-term performance and fosters departmental openness.

- Builds interdisciplinary teams.

IBP can be viewed as a useful instrument to assist businesses in overcoming their issues by improving their capacity for decision-making. IBP is actually regarded as the ideal procedure and strategy for combining all of the organization’s financial and operational data. In fact, by connecting strategic goals with sales, operational, and financial plans, it can help businesses maximise production and better understand how capabilities, resources, and results relate to one another.

S&OP vs IBP: Understanding the Key Differences in Business Planning Processes

The most effective means of elucidating the fundamental distinctions between S&OP and IBP is through my insightful conversation with Gabriel Werner on “The Supply Chain Show,” which serves as my prime reference point. You can find the embedded episode below.

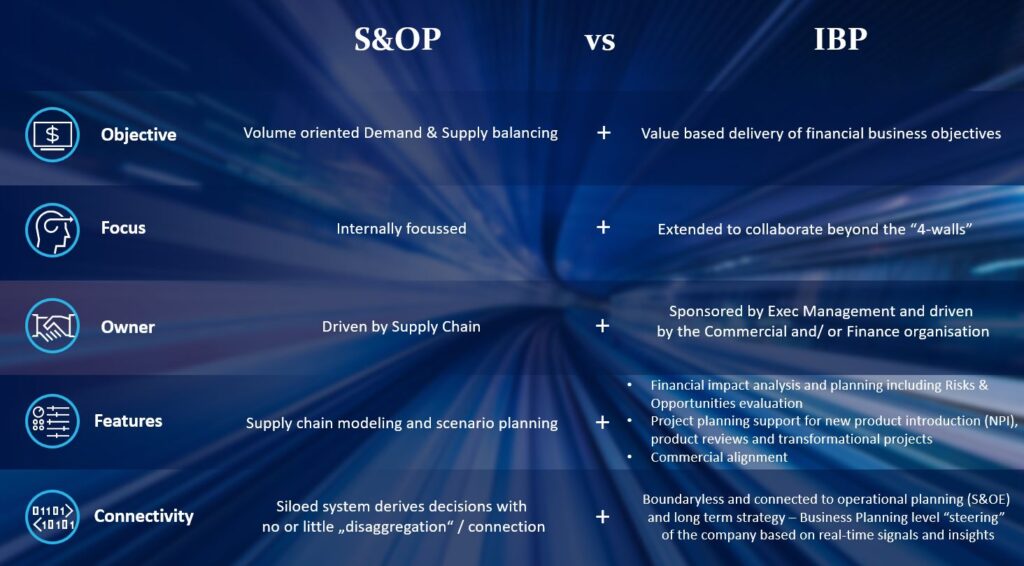

The key takeaways from our conversation are displayed in the graphic below.

Image Copyright- S&OP vs IBP: BlueYonder

Thus, we arrive at the same conclusion as our starting point: that IBP is indeed an extension of S&OP. Attaining maturity in S&OP presents its own set of challenges, as I have elaborated upon in this video. In the mid-to-short term, organizations aim to reach a heightened level of S&OP maturity before embarking on a journey to embrace IBP. However, adopting IBP comes with its own array of challenges to overcome, as explained further below.

Problems in transitioning from S&OP to IBP

- Attract major customers and suppliers

- Model finances in an agreed-upon way of handling complexity: discounts, discounts, exchange rates, pricing, etc…

- Consider business goals: market share/growth, channels, impact

- Business language (EBIT, revenue, cost, margin) instead of supply chain KPI (OTIF, DOH, CTS)

- Change the focus from 1 number plan to managing risks and opportunities

- Include project management to maximize the business impact of new product introduction (NPI)

- From data to insights

Conclusion

The similarities between S&OP and IBP processes are abundant: In order to match forecasts with functions and help managers make planning decisions, both require supporting data. The problem is that although though the majority of information is accessible, it is rarely presented in the appropriate format.

In order to draw a conclusion, and after understanding the significance of each of the two processes in the industrial environment, in particular, after addressing their unique characteristics and distinctions, we had the chance to learn about a variety of aspects of each process as well as its difficulties.

It is noteworthy that there are differences at different levels, including goals, priorities, affiliate departments (owner), features, and connectivity.

IBP begins with the organization’s financial forecast, as previously stated. It is entirely distinct from S&OP, which comes from the supply chain and has as its primary objective adjusting production and sales, as a tool to advance the organization.

S&OP is viewed as a method for assisting manufacturers in managing demand and supply by working with the sales and operations department to develop a unified production plan. To create a smooth management process, the IBP is comparable to a business planning process that applies the S&OP concepts to the supply chain, product and customer portfolio, customer demands, and strategic planning.

Due to the fact that S&OP and IBP are methods that were specifically designed to ensure the effectiveness of the supply chain, it is important to keep in mind a number of steps that must be followed in order to achieve the desired results.

Feel free to post a remark if you would want to add more to the discussion of S&OP vs IBP from your own personal experience.

Special Note: This video is sponsored by Blue Yonder

Frequently Asked Questions (FAQs)

What is S&OP?

Sales and operations planning is known as S&OP. It is a method that aids businesses in matching their operational plans with sales estimates in order to maximize stock levels, output potential, and customer service.

What is IBP?

Integrated Business Planning is referred to as IBP. It is a more sophisticated version of S&OP that goes beyond the alignment of sales and operations. IBP combines financial, strategic, and demand planning to give the organization a complete picture and improve decision-making.

What is the difference between S&OP and IBP?

S&OP focuses primarily on sales and operational alignment, while IBP takes a more comprehensive approach by integrating financial planning, strategic planning, and demand planning. IBP provides a broader perspective and enables organizations to align their business plans with their financial goals and strategic objectives.

What are the benefits of implementing S&OP or IBP?

Implementing S&OP or IBP can bring several benefits, including improved demand forecasting accuracy, better inventory management, enhanced customer service, increased operational efficiency, optimized resource utilization, and improved financial performance.

How does S&OP or IBP contribute to supply chain management?

S&OP and IBP aid organizations in coordinating their supply chain operations with their corporate objectives and client demands. These procedures improve supply chain performance overall, enabling better demand and supply balancing, increase supply chain visibility, and promote collaboration between various functions.

What are the key steps involved in implementing S&OP vs IBP?

Establishing a cross-functional S&OP/IBP team, outlining precise roles and duties, obtaining and analyzing data, creating demand and supply plans, holding frequent S&OP/IBP meetings, and tracking performance against goals are some of the crucial tasks in adopting S&OP or IBP.

Are there specific software tools available for S&OP or IBP?

Yes, there are several software solutions and platforms for supporting S&OP and IBP processes available on the market. These technologies make it easier for organizations to see and manage their planning processes by streamlining data analysis, forecasting, scenario planning, and decision-making.

How can S&OP or IBP drive business growth and competitiveness?

S&OP and IBP enable organizations to make informed decisions, predict and adapt to market changes, optimize resource allocation, increase customer happiness, and promote overall business growth and competitiveness through the alignment of sales, operations, finance, and strategy.

–

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram