Organizing and optimizing complex supply chains can be difficult, but with the help of a Supply Chain Control Tower, it’s possible to coordinate, integrate and manage better. An excellent control tower garners insights from orders, inventory, shipment, and supplier data, then displays them all in real time for improved decision-making capabilities. More visibility makes for a more agile chain that benefits both customers and environmental goals within the business operation objectives. In addition, it allows supply chain stakeholders to quickly and efficiently anticipate issues that could arise before they happen. Thanks to a control tower, organizations can quickly achieve their goals by having an optimized supply chain across all aspects of operations.

[Read More: Evolution of Supply Chain Management and Logistics]

What is a Supply Chain Control Tower?

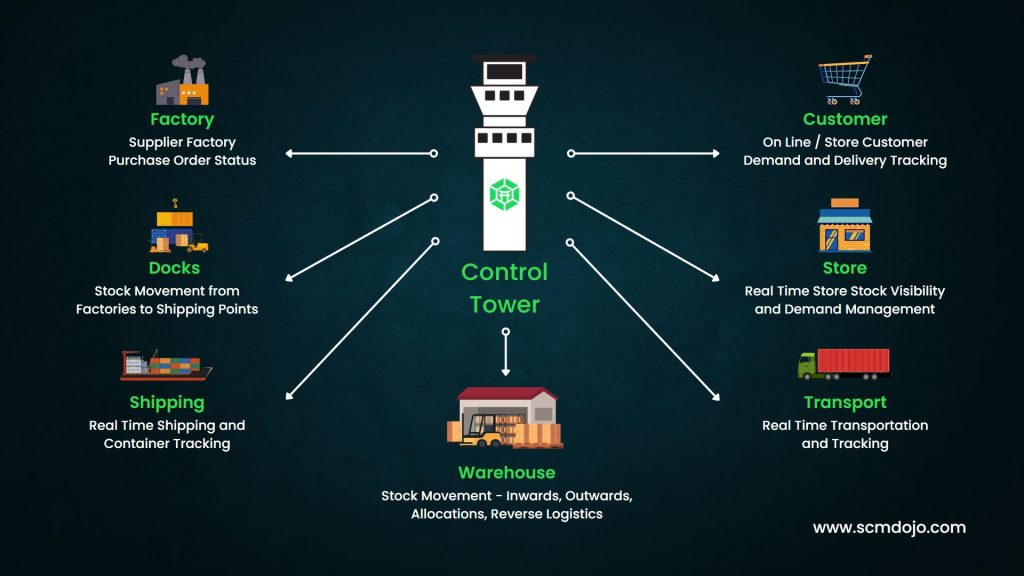

A Supply Chain Control Tower is a centralized platform or system that provides end-to-end visibility, control, and management of a company’s supply chain operations. It acts as a command center, aggregating and analyzing data from various sources across the supply chain, such as orders, inventory, shipments, suppliers, and external events.

The Supply Chain Control Tower is necessary for successfully orchestrating the entire Supply Chain Network. It allows you to monitor and oversee your supply chain at all times, with real-time data providing unprecedented visibility. As a result, it can quickly identify potential issues, such as disruption caused by delivery delays or stockouts.

In addition, the control tower can anticipate potential problems and take preemptive measures to meet customer needs by utilizing predictive analytics. Thanks to its powerful capabilities, the Supply Chain Control tower is essential for optimizing your supply chain performance. A Supply Chain Control Tower collects and displays real-time data by connecting and integrating data from different sources, such as orders, inventory, shipments, suppliers, and external events. It uses cloud, IoT, and AI technologies to process and analyze the data and provides visibility and insights through dashboards, alerts, and reports.

[Read More: Challenges Faced During The Digital Transformation of Supply Chains]

Some of the specific features of a Supply Chain Control Tower are:

- Data management. A control tower collects and stores data from various sources across the supply chain, such as orders, inventory, shipments, suppliers, and external events. It uses cloud, IoT, and AI technologies to process and integrate the data and ensure its quality and accuracy.

- Business intelligence and analytics. A control tower analyzes and visualizes the data to provide insights into the current and future state of the supply chain, such as demand and supply patterns, risks and disruptions, performance, and improvement opportunities. It also uses predictive and prescriptive analytics to forecast and optimize scenarios and trade-offs.

- Performance management. A control tower measures and monitors the key performance indicators (KPIs) and metrics that evaluate the supply chain efficiency, effectiveness, and customer satisfaction, such as service levels, fill rates, lead times, costs, and emissions. It also provides dashboards, reports, and alerts to track and communicate the results.

- Actionable insights. A control tower offers recommendations and guidance for decision-making and action-taking based on wisdom and performance data. It also enables collaborative information sharing and resolution across the supply chain network using tools such as resolution rooms and digital playbooks. It also automates exception flagging and handling to improve speed and accuracy.

What is Supply Chain Orchestration?

Through Supply Chain Orchestration, businesses have the potential to cultivate an efficient and responsive supply chain that improves performance while controlling costs. This coordination mechanism integrates multiple supply chain components, such as logistics, transportation, inventory management, customer service, and manufacturing. This orchestration enhances visibility and automates the supply chain process by providing a centralized platform for monitoring, alerting, and controlling the entire network. Companies can use these technologies to increase customer satisfaction through better customer service response times and efficiently manage their operations. In short, Supply Chain Orchestration has become integral in managing modern-day supply chains.

How to integrate a Supply Chain Control Tower – Orchestration process?

Integrating a Supply Chain Control Tower – The orchestration process involves a few steps.

- Build a supply chain network that connects suppliers, producers, distributors, wholesalers, and customers.

- Establish a communication infrastructure that connects the supply chain partners. This includes software and systems for communication, collaboration, and data sharing.

- Integrate data from suppliers, producers, distributors, wholesalers, and customers, into the supply chain management system.

- Use analytics and machine learning to identify trends and patterns in the supply chain.

- Set up rules and policies for supplier, product, and customer data management.

- Establish supply chain controls to monitor the inventory and performance and trigger the supply chain orchestration processes.

- Automate the supply chain orchestration process to synchronize the communication, data, and controls across the supply chain.

- Monitor, measure, and adjust the supply chain orchestration process when needed.

- Data quality and accuracy are crucial for supply chain control towers. Only complete, updated, consistent, and correct data can lead to good decisions and actions, reducing the system’s value and user trust. Therefore, it’s essential to have reliable data for informed decisions and practical activities.

The benefits of an effective Supply Chain Control Tower – Orchestration

An effective Supply Chain Control Tower – Orchestration process helps streamline and optimize your operations with multiple uses. Here are a few:

- Improved decision-making – You can make more effective, data-driven decisions with improved supply chain visibility.

- Reduced inefficiencies – Automating supply chain processes can eliminate manual errors and improve efficiency.

- Increased agility – Automating supply chain processes allows you to react quickly to changes and adapt to customer needs or market conditions.

- Enhanced collaboration – Your supply chain partners and customers benefit from better collaboration and communication when the process is automated.

- Improved customer service – With enhanced visibility and control, you improve customer service by providing timely order completion and accurate delivery.

- Reduced cost – Automating supply chain processes can help reduce costs by eliminating manual labor, increasing efficiency, and improving collaboration.

- A control tower can improve decision-making capabilities by providing predictive and prescriptive analytics, which can help to anticipate and mitigate risks, optimize trade-offs, and execute scenarios. It also enables collaborative information sharing and resolution, which helps to coordinate and align actions across the supply chain network.

- An optimized supply chain can benefit environmental goals by reducing waste, emissions, energy consumption, and resource use. It can also support circular economy principles like reuse, recycling, and remanufacturing. An optimized supply chain can leverage technologies such as AI, IoT, and blockchain to monitor and measure environmental impacts and implement sustainability strategies and practices

- Demand and supply insights. A control tower can provide insights into the current and future demand and supply patterns across the supply chain network, such as customer orders, inventory levels, production plans, and supplier deliveries. It can also help to forecast demand and supply changes and run simulations of different scenarios and trade-offs.

- Risk and disruption insights. A control tower can provide insights into the potential risks and disruptions that may affect the supply chain performance, such as weather events, traffic delays, quality issues, or supplier failures. It can also help to anticipate and mitigate risks and provide alerts and recommendations for recovery actions.

- Performance and improvement insights. A control tower can provide insights into the key performance indicators (KPIs) and metrics that measure supply chain efficiency, effectiveness, and customer satisfaction, such as service levels, fill rates, lead times, costs, and emissions. It can also help to identify issues, gaps, and opportunities for improvement and provide suggestions for best practices and optimization actions.

Supply Chain Digitalization Assessment Tool (FREE)

Supply Chain Control Tower Case Studies

Here are some case studies to illustrate the benefits of the Control Tower process:

- IBM Supply Chain: IBM implemented a more ingenious control tower solution that leveraged AI to improve inbound supply assurance and the speed of mitigating supply disruptions. The solution enabled IBM to reduce supply shortages by 25%, improve on-time delivery by 15%, and lower inventory levels by 10%.

- A major global manufacturer: The company established a supply chain management hub, or control tower, to coordinate and consolidate efforts to manage the semiconductor chip shortage crisis. The control tower helped the company to optimize chip allocation, reduce order cancellations, increase customer satisfaction, and gain market share.

- Partnership for Supply Chain Management (PFSCM): PFSCM is a nonprofit organization that provides health commodities and supply chain solutions to low- and middle-income countries. PFSCM used One Network’s control tower platform to execute all its critical operational functions, from requisition management to order placement and logistics execution. The platform helped PFSCM to increase visibility, efficiency, and agility across its global network of suppliers, partners, and customers.

Supply Chain Control Tower Challenges and Risks

According to some sources, some of the potential challenges or risks associated with the Supply Chain Control Tower process are:

- Lack of clarity on the span of control. It is essential to define the scope and objectives of the control tower and align them with the business strategy and customer needs.

- Resistance when breaking down functional silos for end-to-end visibility and control. A control tower requires cross-functional collaboration and data sharing among different stakeholders in the supply chain, which may encounter organizational barriers or cultural resistance.

- Questions on actual data ownership. A control tower relies on data from various internal and external sources, which may raise data quality, security, privacy, and governance issues. Establishing clear roles and responsibilities for data management and access is essential.

- Required talent. A control tower demands a combination of skills and competencies, such as analytical, technical, operational, and business acumen. Finding and retaining the right talent can be challenging in a competitive market.

- Ambivalence on a build-versus-buy decision. A control tower can be either built in-house or bought from a vendor, depending on the specific needs and capabilities of the organization. Trade-offs between customization, cost, speed, and scalability must be carefully evaluated.

- Inability to identify the right technology requirements. A control tower involves complex technologies like data platforms, analytics tools, artificial intelligence, machine learning, and cloud services. Choosing and integrating the right technology stack with existing systems can be daunting.

These challenges can be overcome by following some best practices, such as:

- Conducting a thorough assessment of the current state and desired outcomes of the supply chain.

- Developing a clear business case and roadmap for the control tower implementation.

- Engaging key stakeholders and sponsors throughout the process.

- Leveraging proven methodologies and frameworks for control tower design and deployment.

- Adopting an agile and iterative approach to test and learn from pilots and prototypes.

- Partnering with experienced vendors and consultants who can provide guidance and support.

To Conclude

In conclusion, the Supply Chain Control Tower – Orchestration process is crucial for any well-run and effective supply chain organization. The increased visibility and improved collaboration it provides are essential for businesses to remain competitive. By utilizing automation and analytics, companies can increase agility and reduce costs, improving customer service and satisfaction. Organizations that have successfully adopted the supply chain control tower-orchestration process have significantly improved their bottom line and increased customer retention.

Organizations must invest in a Supply Chain Control Tower – Orchestration system to manage their supply chain processes and remain competitive. With the right design, businesses can increase transparency, reduce costs, and collaborate effectively with their supply chain partners.

–

Arindam Mukherjee is a seasoned Supply Chain Operations Architect with a focus on driving digital transformation. With over 18 years of experience in the field, Arindam has honed his expertise in a wide range of industry verticals and has been involved in implementing and integrating various Enterprise Resource Planning (ERP) systems, as well as spearheading digital transformations.