Artificial intelligence, machine learning, big data, blockchain – the list of emerging digital technologies is long. There is much discussion on their application and use and they are omnipresent in today´s society. Furthermore, they also have large impacts on companies and especially their supply chains. Companies realize that they do not only need to look and optimize company-internal procedures but also take into account their supply chain network and collaborating parties. This results in increased attention towards supply chain-related topics. As Rice and Hoppe stated:

“The more likely scenario will find companies competing – and winning – based on the capabilities they can assemble across their supply networks.”

(Rice and Hoppe 2001). Expectedly, this also holds true for digitalization initiatives.

Exemplary benefits connected to the supply chain digitalization are: Increased sales, greater business efficiency, costs savings, higher flexibility, novel forms of customer experience including higher customer experience and customer satisfaction – the list is long. A study found out that digital transformation can reduce costs by 7% to 34% and can lead to additional revenues by 22% to 33%, depending on the industry (Kersten et al. 2017). However, precise quantification is difficult as the process involves many actors across company borders and a long time horizon needs to be considered.

In today´s business market, we witness the entrance of young companies with newly developed business models which, in the first place, are only possible because of digital technology applications. Examples are Picnic or Gorillaz using the upcoming trend of grocery delivery. Digitally transformed supply chains enable complex tour planning systems, intelligent forecast mechanisms, and optimized transport capacities (Kersten et al. 2017). Yet, also long-established companies need to leverage the opportunities of transformation. A successful example for an incumbent is L’Oréal, describing itself as a “Digital First” company. Through digital transformation, the company serves the current need for personalization, for example with their virtual makeup app which allows customers to try on makeup using augmented reality (L´Oréal 2020).

PhD Thesis – Enhanced Supplier Development Framework

Besides the publicly shared success stories, companies often struggle to adapt their way of doing business. During the COVID-19 pandemics, the vulnerability of today´s supply chains became alarmingly obvious. It was a “wake-up call” for many companies and the crisis has strengthened the claim to make use of digital technologies. It has successfully accelerated technology usage in many areas, bringing the digital transformation even more to the forefront of many companies´ agendas (LaBerge et al. 2020). But even with the latest advancements, a recent study reveals that there still is a lot of unused potential in supply chains. “Just 8% [of companies worldwide] have achieved digital maturity across six key components of supply chain operations: warehousing and logistics, procurement, inventory management, supply planning, demand planning and management, and supplier risk management” (Harward Business Review Analytical Service 2021).

From an academic point of view, the topic offers great potential to improve current supply chains and develop or test different theories. However, many concepts remain unclear as the topic is still emerging. In this blog article, we want to share our findings from a research paper published in the “Lecture Notes in Logistics 2021”. In a recent study, we explored the preconditions and challenges regarding the digital transformation of supply chains (Hellweg et al. 2021). First, we performed a structured literature review to identify the preconditions and challenges in academic literature. Second, we discussed the results with practitioners to capture their point of view on the importance of the identified preconditions and challenges. (For details see Hellweg et al. 2021.)

Structure of Supply Chain Digitalization

We follow the definition by Verhoef et al. and understand digitalization as “how IT or digital technologies can be used to alter existing business processes” to improve current processes and structures and to seize new business opportunities (Verhoef et al. 2021, p. 891). Our focus is on major changes to enterprises and their supply chains.

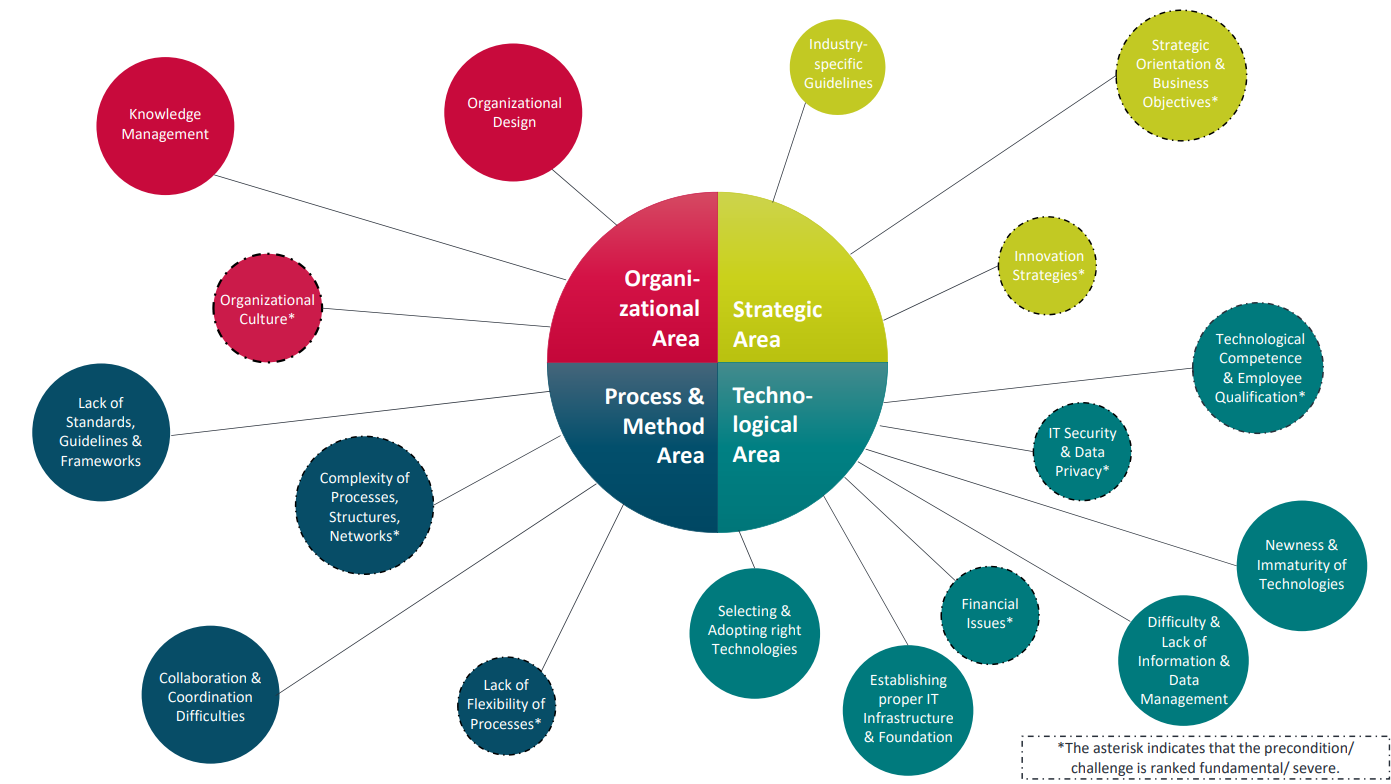

To structure the large topic area of supply chain digitalization, we organize it into four areas: the strategic, organizational, process & method, and technological areas. The first area, strategic digitalization considers issues like strategy formulation, new forms of digital governance along supply chains or other steering- and control-related functions. The second area, organizational digitalization, covers more “soft” topics like employee development or the cultural mindset. Third, the process & method digitalization area considers the adaptation of supply chain-related processes taking into account collaboration and coordination efforts. Last but not least, technological digitalization is the most prominent area in literature. Here the application of new technologies like smart objects is included, besides the set up of appropriate technological infrastructure and architecture along supply chains, or IT security aspects. We identify and discuss preconditions for the first two, and challenges for the latter two areas, presented in Figure 1.

Figure 1: Preconditions and Challenges for the Digitalization of Supply Chains

(Adapted from Hellweg et al. 2021)

Preconditions for the Digitalization of Supply Chains

The occurrence of the preconditions in academic literature is relatively balanced. This hints at the perceived equal importance of the different preconditions in academia. However, contrasting this with a practitioner´s opinion, we spot important differences. The strategic orientation and business objectives are considered fundamental. This is supported by literature, claiming that every digitalization initiative needs to be related to the strategy and have clear business goals. Digitalizing something because of “the sake of digitalizing” can be problematic. Furthermore, innovation strategies are perceived as important: to be able to continuously transform and adapt the value creation. In supply chains, the potential does not necessarily lie in the products but in the services that can be offered to better suit the customer’s needs. In addition, the organizational culture is a “showstopper” for many digitalization projects based on the practitioner´s experience. To have a certain mindset, e.g., open-mindedness and mutual trust is an important premise. Otherwise, transformation efforts will be overrun by old structures. It is necessary “to recognize the inevitability of the digital transformation and to be open to change” states one interviewee. The organizational culture change is especially challenging when considering many actors along the supply chain. Building trust and collaboration inter-company wide increases the difficulty.

The practitioner identifies the other three preconditions as supportive. Industry-specific guidelines are highlighted in the literature as supportive tools for transformation initiatives and highly beneficial. In contrast to that, the interviewees point out that often the application cases and companies are diverse, even when belonging to the same industry. This hinders a universal application of guidelines, especially when the degree of adaptability of the guidelines is limited. Regarding knowledge management, the interviewees share their experience in hiring consultancies if knowledge in specific areas is necessary. This might be a short-term solution; however, it can support companies starting digital transformation initiatives. In the long run, it can strengthen the relationship with suppliers and customers engaging in innovative projects, and lead to building knowledge in the company. The right organizational design is important for intra- and inter-company scenarios. However, the interviewees perceive this to be a supportive precondition because the design facilitates digital transformation initiatives, but does not impede them altogether.

Challenges for the Digitalization of Supply Chains

Also, the challenges are first identified in the literature and afterward discussed in an interview to include the view of practitioners in our research. In the interview, the challenge of the complexity of underlying processes, structures, and networks is rated as one of the most difficult challenges. This is not reflected adequately in literature. The practitioner expresses that often processes are not thoroughly understood and analyzed before digitizing them. This indicates that the context of processes needs to be considered to reach impactful results. This, however, is difficult in the supply chain context as it involves cross-functional as well as cross-company processes. The interviewee states that: “A common problem is that processes are not fully understood and then just digitized without improving them. If you simply digitize an inefficient process, you end up with an inefficient process that is digital”.

The challenge of lack of flexibility is also assessed as a severe challenge. However, the interviewee notes that rather people and their resistance to change cause inflexibility than the processes themselves. Furthermore, financial issues are identified as the most challenging in the technological area. The late amortization of digitalization makes it difficult to argue business cases. This is further complicated by the difficulty to quantify the benefits. It is especially difficult to convince all parties along the supply chain to participate when the advantages are only realized in some parts of the chain.

The challenge of technology competence and employee qualification is also assessed as severe. There is an ever-growing number of new technologies, the training is time-consuming, and the high pace of change makes it more difficult to be up-to-date. Furthermore, supply chain managers are often not information technology experts. Functional as well as technological knowledge needs to be merged. Finally, yet importantly, IT security and data privacy issues are assessed as severe challenges by the interviewee. Often, the weakest link in a chain is attacked and with spreading a virus throughout increasingly connected supply chains, real harm can be done.

The expert ranks all other challenges as moderate. Additionally, according to the expert, the challenge of changing information systems and other structures during ongoing operations is often underestimated. A current system cannot be put on hold and experiments often need to take place in day-to-day business. When asked what is perceived as the biggest hurdle overall, it is stated that the importance of proper change management can hardly be overestimated.

Conclusion and Outlook

The digital transformation of companies´ supply chains is on the top of many enterprises’ agendas. It is among the top trends to watch. Practitioners explore the benefits associated with it. Also among researchers, it is a “hot topic” and they try to keep up with the latest developments. The topic is multidisciplinary and extremely complex, thus slowing down the progress and increasing the challenge of conceptualizing it. Our results of the paper presented at the Logistics Management Conference 2021 give scholars a baseline to start their research endeavors. We present the preconditions and challenges identified in the academic literature that should be exploited more in-depth. Further research should also explore countermeasures. Practitioners can use the insights to avoid pitfalls that have already been identified and mitigate problems in advance of transformation projects. Collaborations between academia and practitioners can lead to mutually fruitful results, especially in such relevant and current topics much shaped by practical experiments and advancements.

We expect to see growing interest in this topic area in the future and are excited what the supply chains of tomorrow will look like.

Remark: This article is based on the following contribution on the Logistics Management Conference 2021: Hellweg, Frauke; Meierkort, Luis; Severin, Tim; Hellingrath, Bernd (2021): Preconditions and Challenges in the Digital Transformation of Supply Chains: Findings from Academia and Practice. In Udo Buscher, Rainer Lasch, Jörn Schönberger (Eds.): Logistics Management. Cham: Springer International Publishing (Lecture Notes in Logistics), pp. 15–32. DOI: 10.1007/978-3-030-85843-8_2

Author Profile

Contact Details:

Leonardo Campus 3

48149 Münster

Phone: +49 251 83-38018

You can also get my PhD research thesis by clicking the below button and learning how Ph.D. thesis is written.

PhD Thesis – Enhanced Supplier Development Framework

References

Harward Business Review Analytical Service (2021): Transforming Supply Chains for Higher Performance and Resiliency. Research Report. Harvard Business Review Analytical Service. Available online at https://hbr.org/resources/pdfs/comm/GEP/TransformingSupplyChains.pdf.

Hellweg, Frauke; Meierkort, Luis; Severin, Tim; Hellingrath, Bernd (2021): Preconditions and Challenges in the Digital Transformation of Supply Chains: Findings from Academia and Practice. In Udo Buscher, Rainer Lasch, Jörn Schönberger (Eds.): Logistics Management. Cham: Springer International Publishing (Lecture Notes in Logistics), pp. 15–32.

Kersten, Wolfgang; Seiter, Mischa; Von See, Birgit, Hackius, Niels; Maurer, Timo (2017): Trends und Strategien in Logistik und Supply Chain Management. Chancen der digitalen Transformation. Hamburg: DVV Media Group GmbH. Available online at http://logistiktrends.bvl.de/system/files/t16/2017/Trends_und_Strategien_in_Logistik_und_Supply_Chain_Management_-_Chancen_der_digitalen_Transformation_-_Kersten_von_See_Hackius_Maurer_2017.pdf.

L´Oréal (2020): 2020 Annual Report. Available online at https://www.loreal.com/-/media/project/loreal/brand-sites/corp/master/lcorp/docments-media/publications/annual-reports/loreal2020annualreport.pdf.

LaBerge, Laura; O´Toole, Clayton; Schneider, Jeremy; Smaje, Kate (2020): How COVID-19 has pushed companies over the technology tipping point – and transformed business forever. McKinsey & Company.

Rice, J.; Hoppe, R. (2001): Supply Chain vs. Supply Chain: The Hype and the Reality. In Supply Chain Management Review.

Verhoef, Peter C.; Broekhuizen, Thijs; Bart, Yakov; Bhattacharya, Abhi; Qi Dong, John; Fabian, Nicolai; Haenlein, Michael (2021): Digital transformation: A multidisciplinary reflection and research agenda. In Journal of Business Research 122, pp. 889–901. DOI: 10.1016/j.jbusres.2019.09.022.

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram